Consolidation of inspection criteria for rigid-flex PCBs

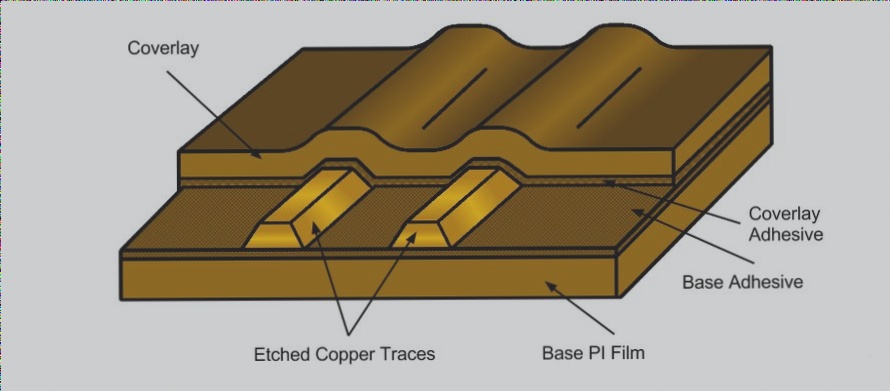

Efficient inspection of rigid-flex circuit boards requires a broad field of view and advanced electronic magnification, as automated systems can only partially replace human inspectors and specialized programs are needed to keep up with miniaturized circuits and increasing density.

Consolidation of inspection criteria for rigid-flex PCBs Read More »