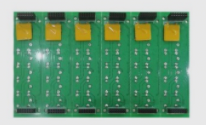

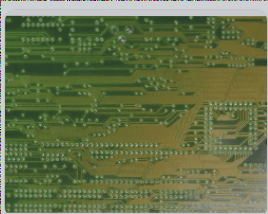

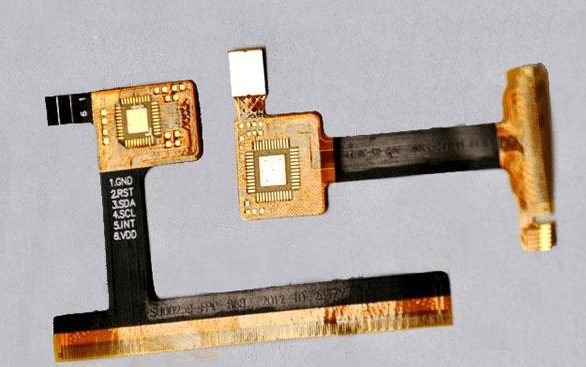

Rigid and Flexible PCB Circuit Board Wiring

PCBs (Printed Circuit Boards) come in rigid, flexible, and rigid-flex types, with variations in thickness, materials, and layers (single-sided, double-sided, or multilayer), offering advantages like high density, reliability, design flexibility, and manufacturability for use in complex electronic systems.