Understanding PCB Teardrops: Exploring PCB Basics and Key Information – Wellcircuits

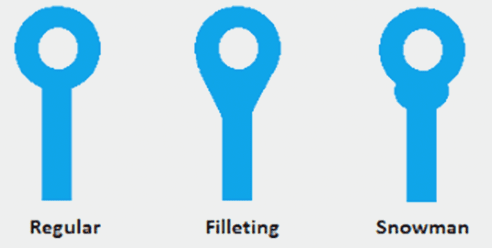

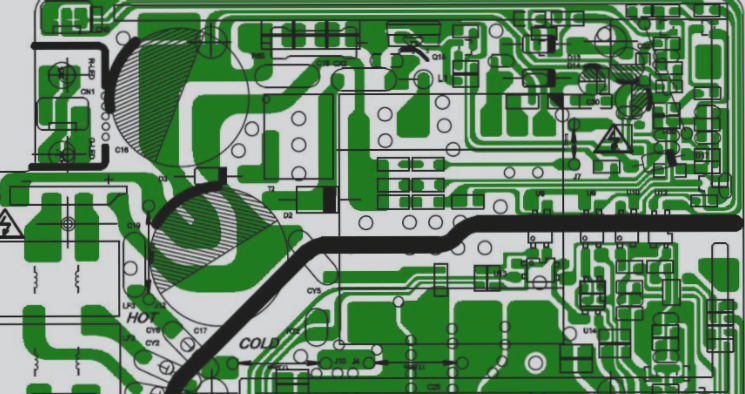

Designing PCBs comes with various challenges including undesirable breakouts due to drill wander misalignment and stress concentration To address these issues one effective technique is the use o

Understanding PCB Teardrops: Exploring PCB Basics and Key Information – Wellcircuits Read More »