Resolving the Issue of FPC Cover Film Overflow

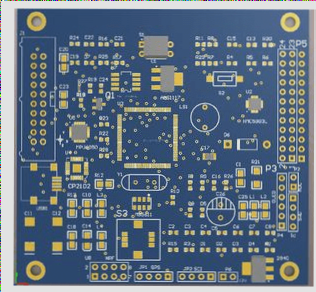

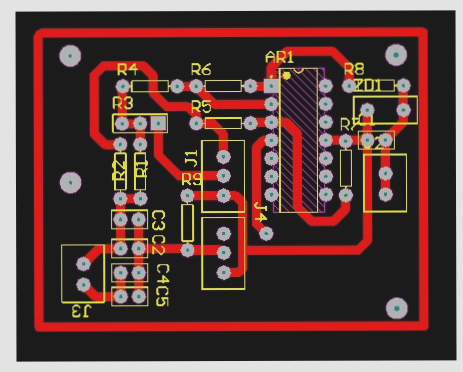

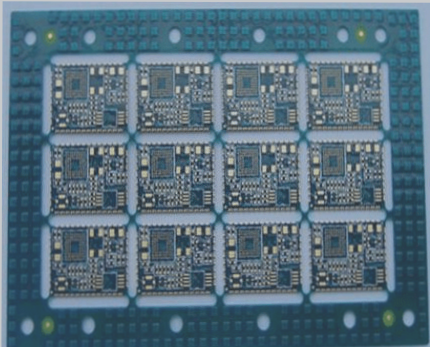

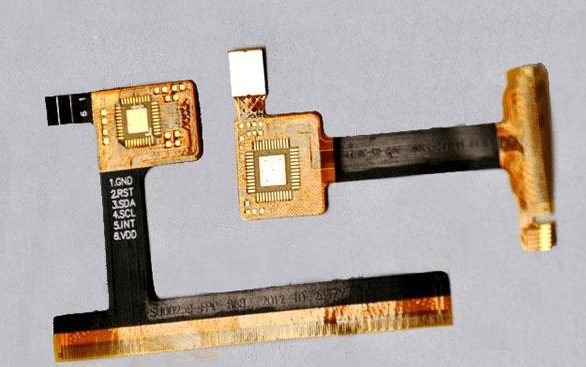

FPC (Flexible Printed Circuit) is a highly flexible, lightweight, and thin circuit board used in various electronics, and TopWin’s MicroVector system utilizes UV lasers for precise, fast, and cost-effective processing, addressing the challenges of traditional methods in small to medium production runs by enabling easier adjustments and improved cut quality.