What is a Stiffener in Flexible PCBs? – PCB Design and Layout – Wellcircuits

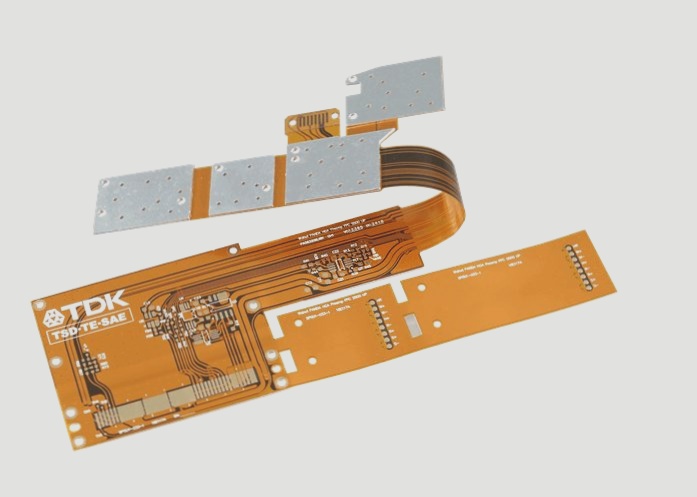

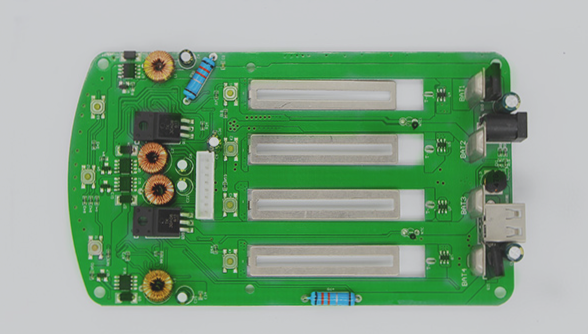

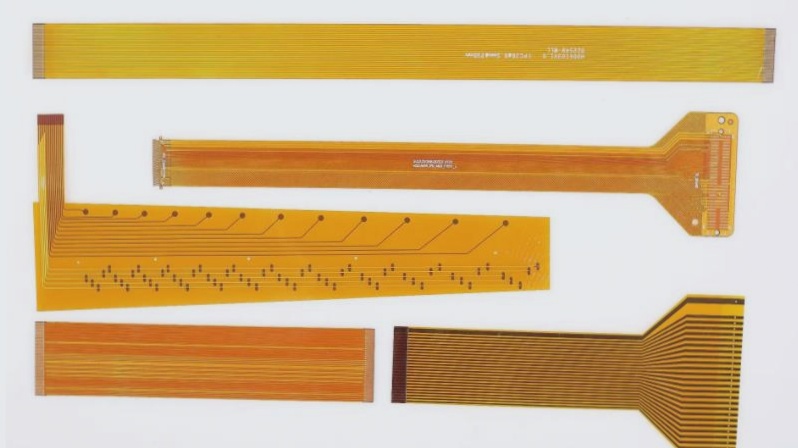

Flexible Printed Circuit Board often called FPC is a kind of circuit board with high reliability and good flexibility using polyimide as the substrate It has the features of lightness thinnesssof

What is a Stiffener in Flexible PCBs? – PCB Design and Layout – Wellcircuits Read More »