Tracking the Development of the FPC (Flexible Printed Circuit) Board Industry

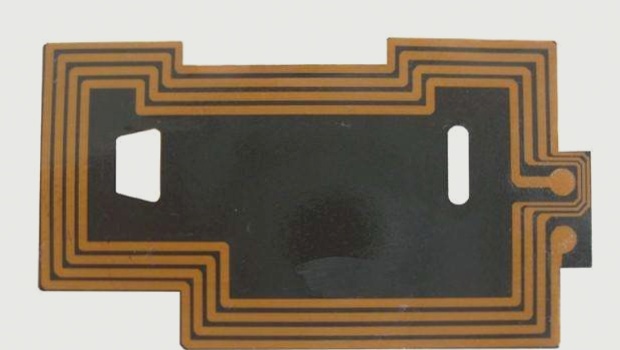

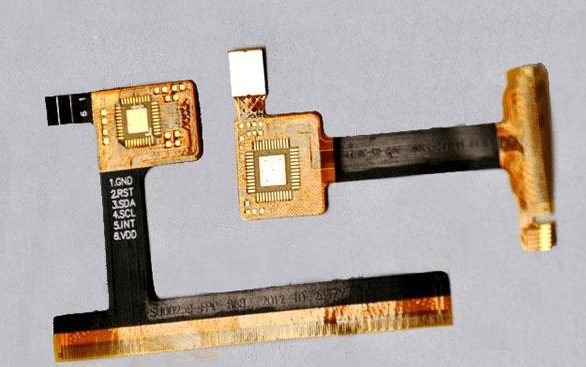

A PCB (Printed Circuit Board) provides electrical support and interconnection for electronic components, while FPC (Flexible Printed Circuit Board) offers increased flexibility and reliability; COF (Chip on Film) technology enhances chip packaging on flexible substrates, with FCCL (Flexible Copper Clad Laminate) serving as a key material for FPCs, and their widespread use is driving advancements in smartphones, automotive electronics, and wearables.

Tracking the Development of the FPC (Flexible Printed Circuit) Board Industry Read More »