Analysis of Issues in Laser Processing of High-Density Flexible Printed Circuits

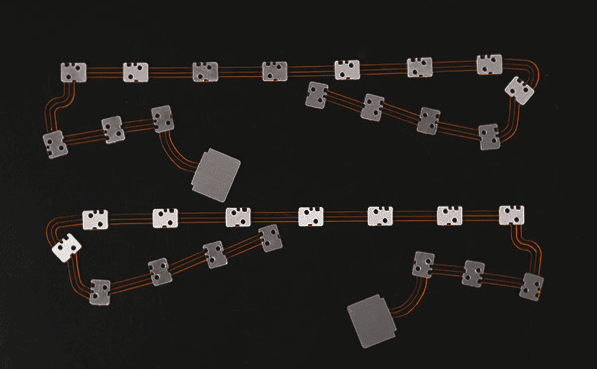

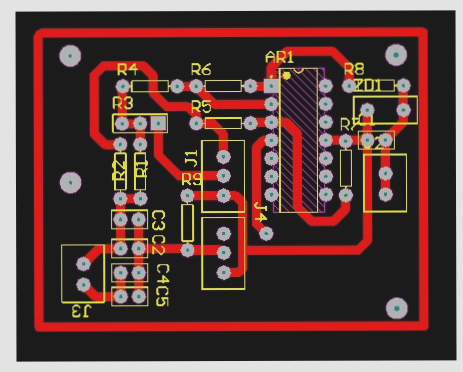

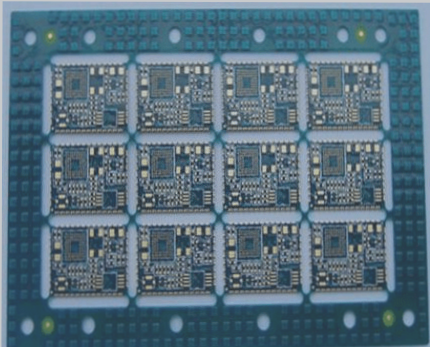

Flexible printed circuits (FPC) offer benefits like space efficiency and weight reduction, with growing global demand, particularly for high-density applications in sectors such as telecommunications and medical devices, emphasizing the advantages of laser technology for micro-via drilling in their manufacturing process.

Analysis of Issues in Laser Processing of High-Density Flexible Printed Circuits Read More »