What materials are used in flexible PCBs, and what are their primary functions?

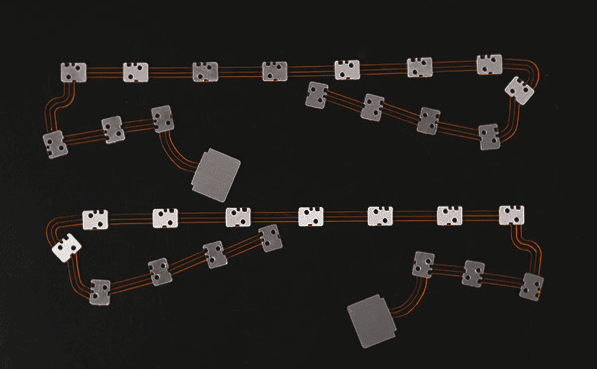

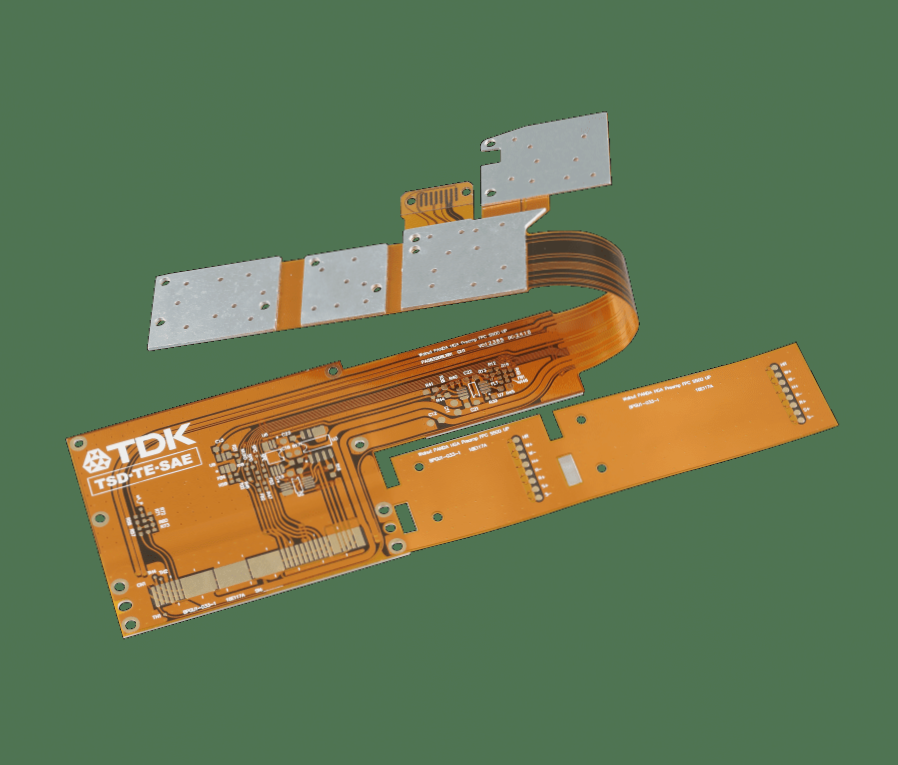

Flexible circuit boards (FPCs) are primarily used in small electronic devices, evolving from military applications to consumer electronics, and feature versatile functions with materials like polyimide and copper foil that ensure high flexibility, heat resistance, and stability.

What materials are used in flexible PCBs, and what are their primary functions? Read More »