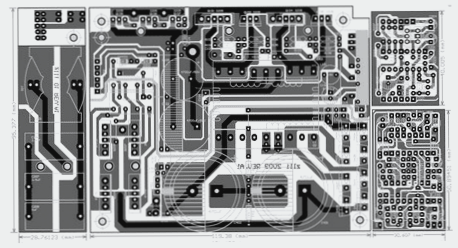

PCBA assembly and soldering process for FPC (Flexible Printed Circuit) boards

FPC assembly requires special handling due to its flexibility and moisture sensitivity, necessitating pre-baking and custom carrier boards for the SMT process, with careful attention to each step to ensure high quality and prevent defects.

PCBA assembly and soldering process for FPC (Flexible Printed Circuit) boards Read More »