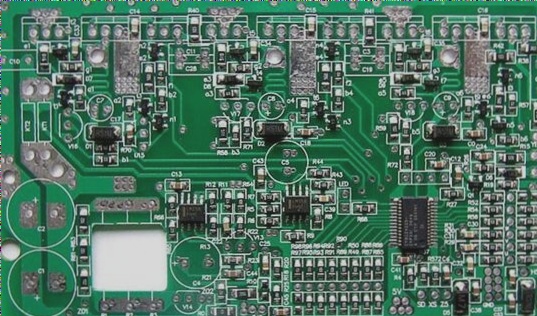

PCBs come in single-side and double-side options, but for more complex circuits, multi-layer boards offer advantages such as high assembly density and improved signal transmission speed, although they come with higher costs and longer processing cycles. WellCircuits Co., Ltd. has advanced equipment and experience in PCB production, including four to six layer boards and practical printed circuit boards with over 100 layers, with advanced technology such as advanced laser drilling and plasma dry etching. The manufacturing process begins with a GlassEpoxy resin substrate and negative transfer printing to create the circuit.