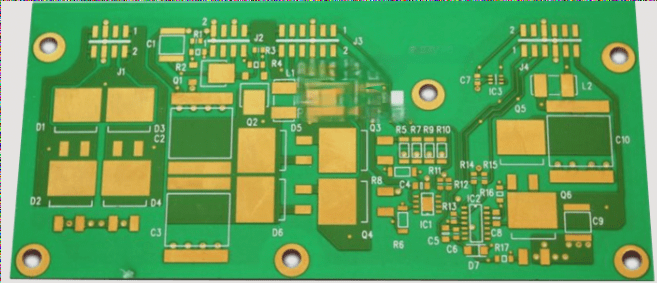

The distinction between rigid and flexible PCB design.

The differences in design approaches for rigid and flexible PCBs, highlighting factors like flexibility, pad placement, trace width, and shape considerations that are crucial for ensuring durability and performance in flexible circuit boards.

The distinction between rigid and flexible PCB design. Read More »