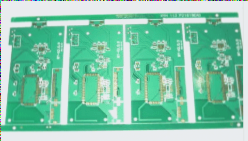

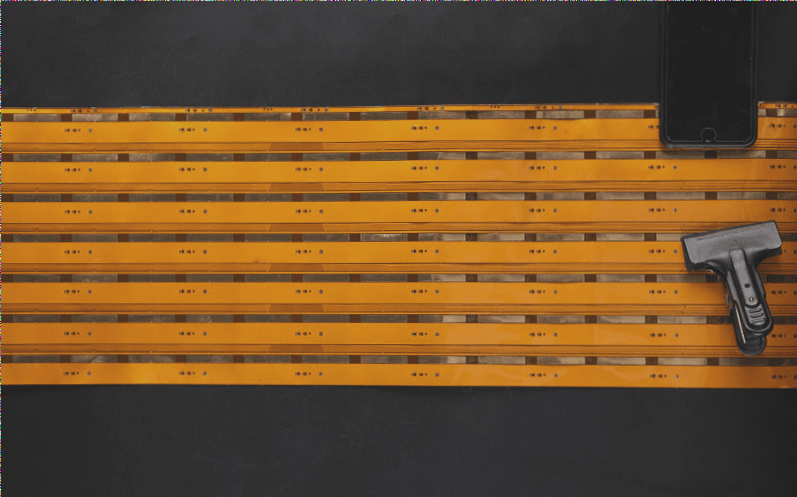

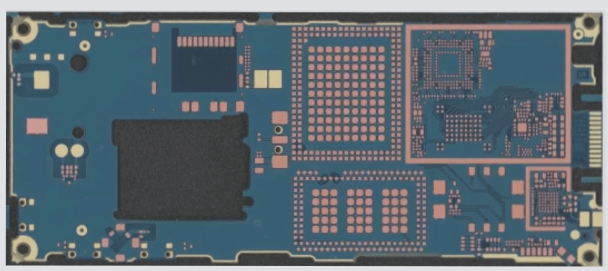

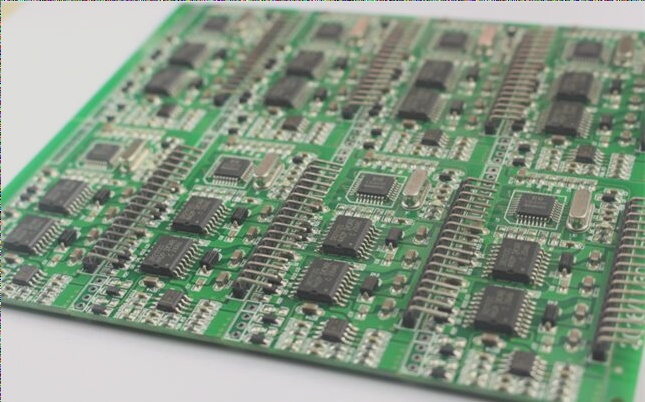

Introduction to Surface Electroplating of Flexible Printed Circuit Boards (FPCs)

The pre-treatment cleaning process and careful control of electroplating techniques are vital for ensuring the quality and adhesion of flexible circuit boards, as contamination and uneven plating can lead to significant long-term issues.

Introduction to Surface Electroplating of Flexible Printed Circuit Boards (FPCs) Read More »