Can you explain the principles of mixed-signal PCB layout design?

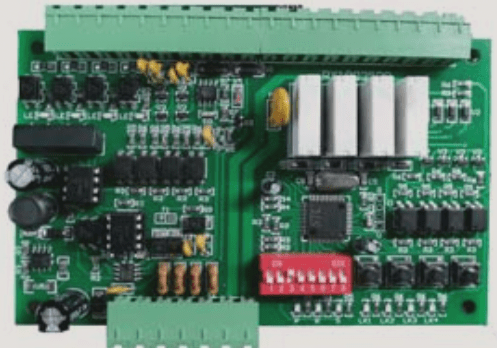

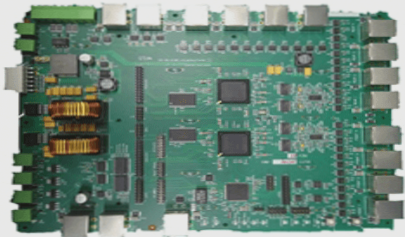

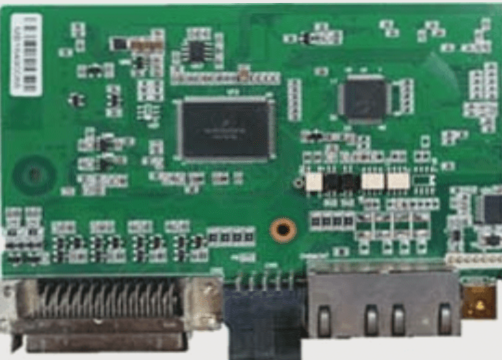

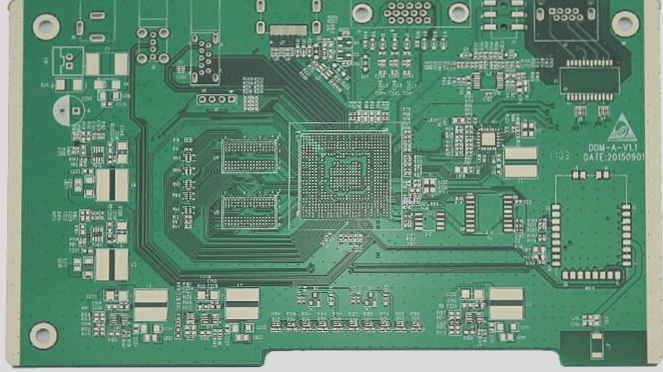

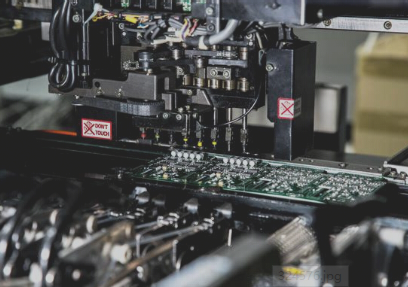

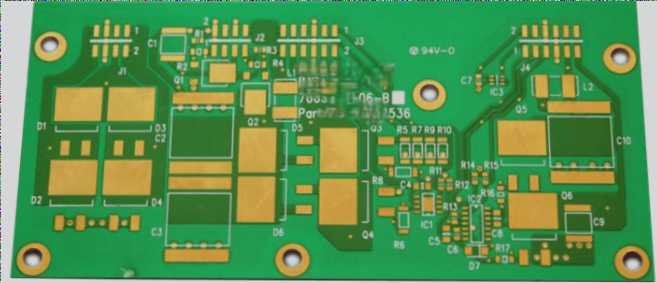

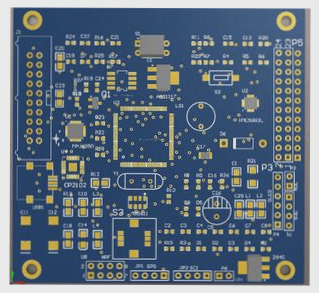

In designing high-density analog and digital circuits for a mixed-signal PCB, it’s crucial to achieve a balance between layout and routing while adhering to specific guidelines for signal integrity, bypass capacitor placement, and component proximity to minimize noise and optimize performance.

Can you explain the principles of mixed-signal PCB layout design? Read More »