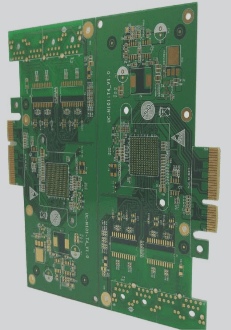

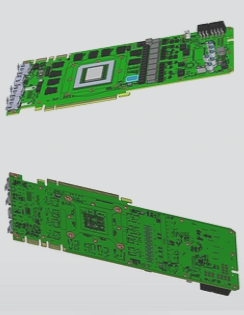

How to calculate the quotation for a PCB circuit board?

The PCB quotation fee includes material, drilling, processing, and management costs, with prices influenced by material type, thickness, and surface treatment processes, requiring a detailed calculation process that varies by product and manufacturer capabilities.

How to calculate the quotation for a PCB circuit board? Read More »