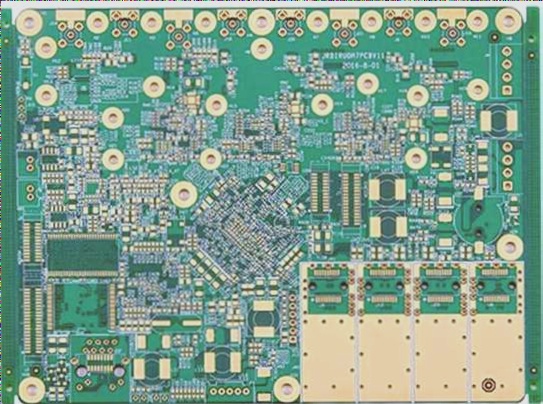

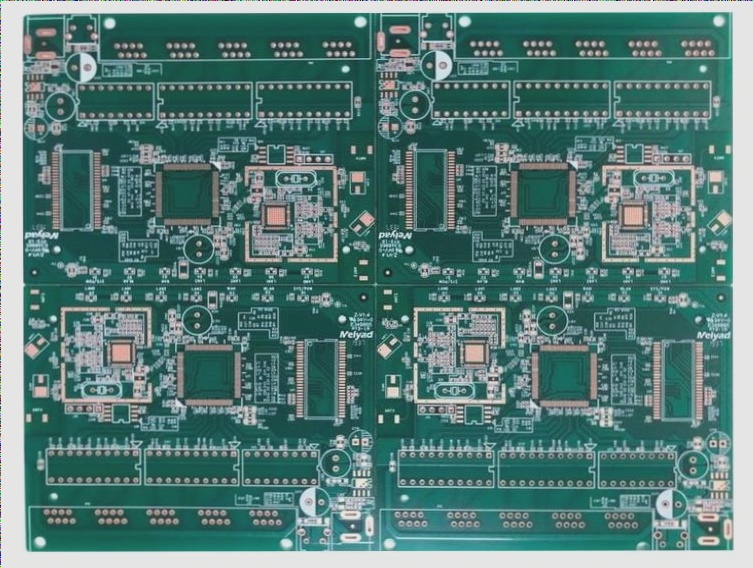

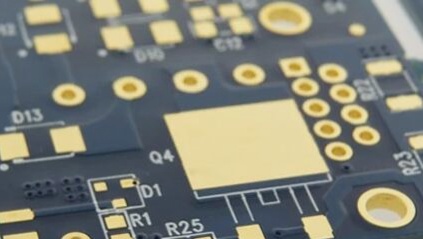

1. PCB plating process: The process begins with pickling, followed by full-board electroplated copper, pattern transfer, acid degreasing, secondary countercurrent rinsing, micro etching, secondary countercurrent rinsing, pickling, tin plating, secondary countercurrent rinsing, countercurrent rinsing, pickling, pattern copper plating, secondary countercurrent rinsing, nickel plating, secondary washing, citric acid treatment, gold plating, and concludes with recycling and 2-3 pure water washes before drying. 2. Remove oxide from the plate surface, activate it, and maintain the acid concentration generally at 5%-10% to prevent instability in the sulfuric acid tank solution due to water introduction. Keep acid leaching brief to prevent PCB board oxidation. Promptly replace acid when turbid or excessively copper-laden to avoid surface contamination of electroplated copper cylinders and plates. 3. Also referred to as “primary copper,” it shields freshly deposited thin electroless copper to prevent post-oxidation acid erosion. The tank solution primarily contains copper sulfate and sulfuric acid, with a high acid and low copper formula ensuring uniform PCB surface thickness distribution and effective plating of deep holes and small apertures. Sulfuric acid content is maintained at 180-240 g/L, copper sulfate around 75 g/L, with trace chloride ions added for gloss enhancement. Typically, 3-5 ml/L of gloss agent per cylinder is used, adjusted based on production outcomes or 1,000 ampere-hours. 4. PCB full-board plating current is typically calculated at 2 amps per square decimeter, multiplied by the board’s platable area. For full-board plating, this equals board length in dm × board width in dm × 2 × 2A/dm². Copper cylinder temperature is maintained around room temperature, preferably not exceeding 32 degrees Celsius, often controlled at 22 degrees Celsius. In hot weather, a cooling temperature control system for the copper cylinder is recommended. The text has been refined for clarity and coherence while maintaining technical details of the PCB plating process and associated considerations.