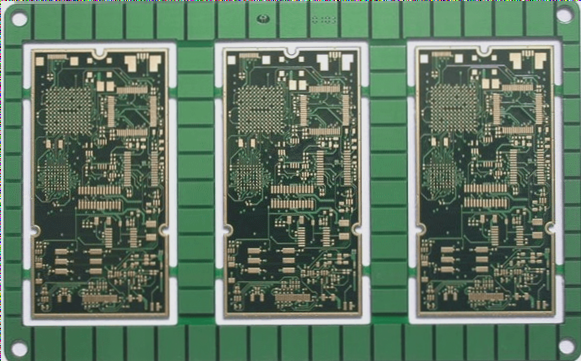

Are you aware that copper is utilized in PCB design?

Copper paving serves to enhance shielding, meet PCB process requirements, ensure signal integrity, and reduce ground wire impedance, while balancing the benefits and drawbacks of solid versus grid copper to optimize performance in digital and analog circuits.

Are you aware that copper is utilized in PCB design? Read More »