PCB reverse engineering and the techniques for component selection

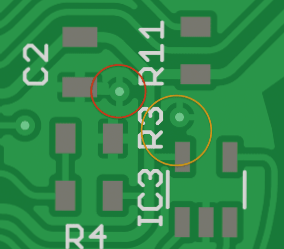

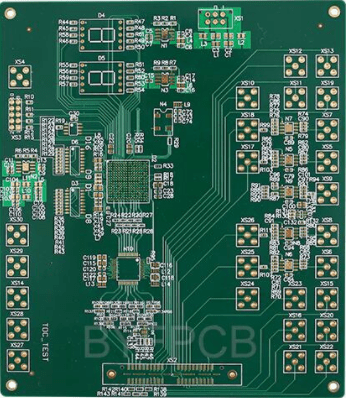

The text provides detailed guidelines for PCB layout design, including optimal component placement for heat dissipation, interference reduction, and maintenance ease, as well as considerations for component selection, routing, and grounding to minimize noise and enhance circuit performance.

PCB reverse engineering and the techniques for component selection Read More »