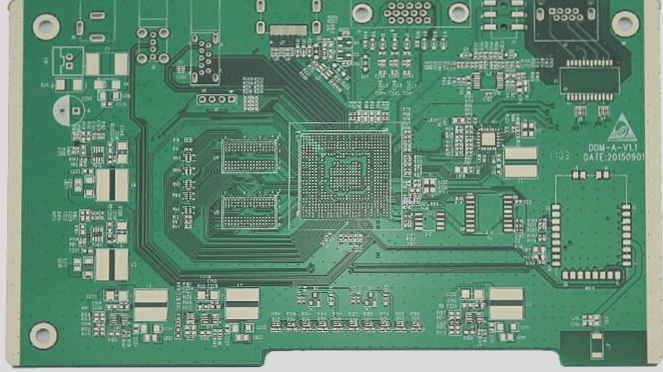

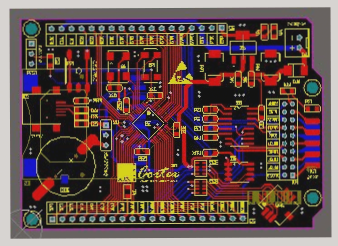

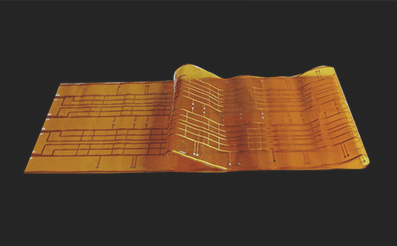

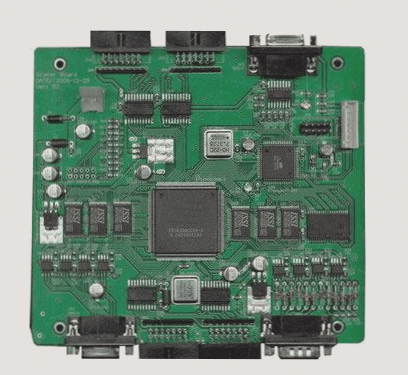

Are you familiar with the principles of high-speed PCB design?

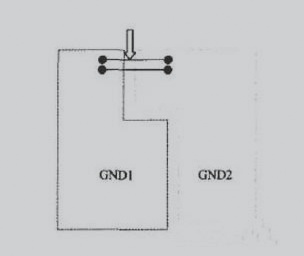

The article outlines essential principles for high-speed PCB layout design, emphasizing factors like signal quality, structural requirements, and thermal considerations, while detailing layout strategies, special component placement, and post-layout verification processes to ensure effective implementation.

Are you familiar with the principles of high-speed PCB design? Read More »