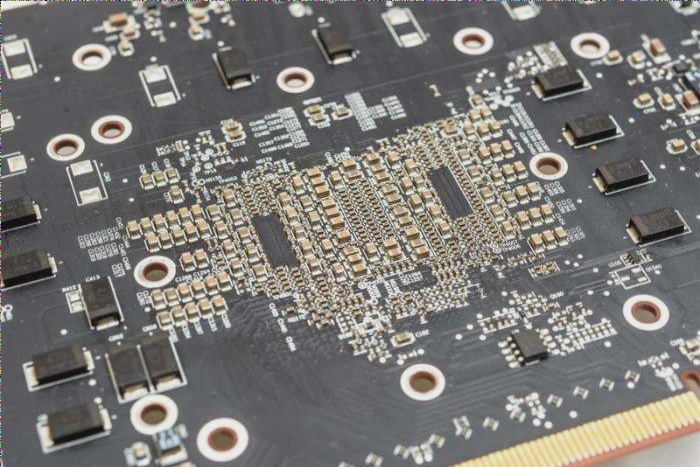

1. Detection methods for polarity and warping in components vary based on visual cues or technological aids like AOI, contingent on the situation and parameter settings. 2. While severe warping and deformation can be easily spotted using methods like AOI, detecting slight warping relies heavily on specific circumstances and parameter adjustments. 3. Tin bridging is generally identifiable, but its detection becomes challenging when it’s concealed beneath components, especially for connectors hidden from AOI inspection. 4. Circuit board production lines employ AOI, ICT, and FVT for quality assurance, with some utilizing AXI, particularly for inspecting solder joints like BGAs, employing X-ray technology along the line.