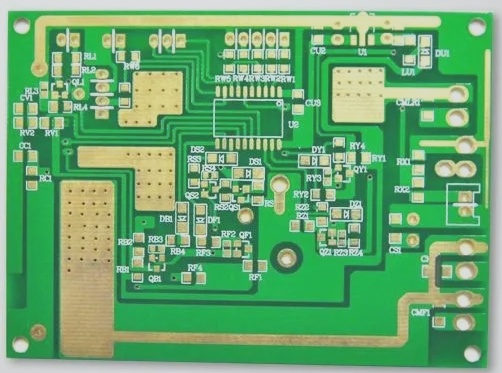

Surface treatments for printed circuit boards (PCBs) encompass various methods like gold plating, tin spraying, immersion gold, immersion silver, and OSP. These treatments cater to different needs, offering advantages such as oxidation resistance, good solderability, and environmental friendliness. Gold plating, though costly, remains vital for high-performance connectors, while tin plating predominates due to lower costs, especially in mainstream electronics like motherboards and memory modules. Immersion gold boards mitigate issues like the tin whisker effect, providing superior solderability and flatness, making them increasingly preferred in modern PCB applications.