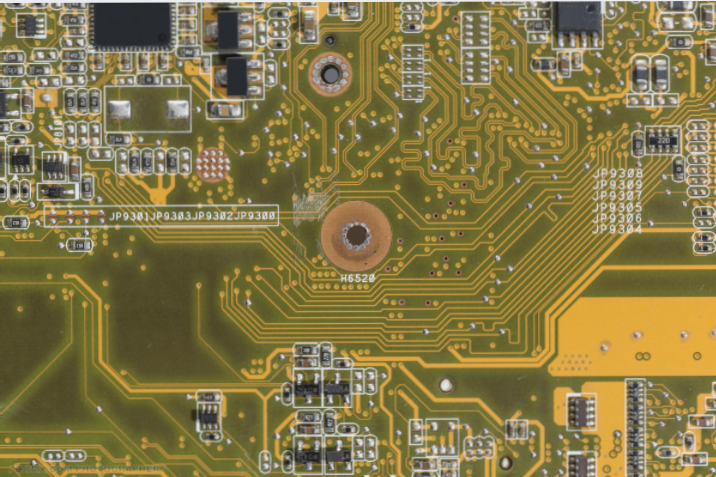

What are the key characteristics of the printed circuit board?

The surface of a PCB may appear uniform, but crucial differences exist that affect its durability and functionality, making high-quality PCBs a worthwhile investment despite higher initial costs, especially in critical applications where failures can have serious consequences.

What are the key characteristics of the printed circuit board? Read More »