PCB Circuit Board Connectors and Procurement Strategies

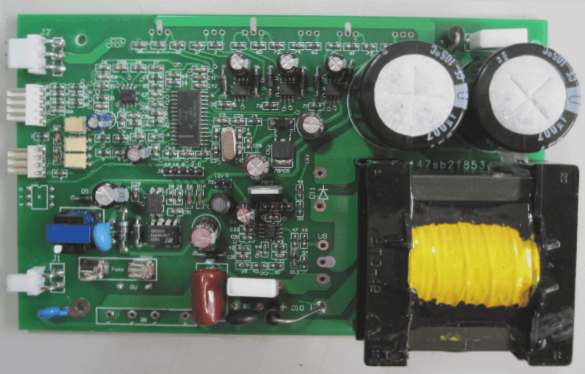

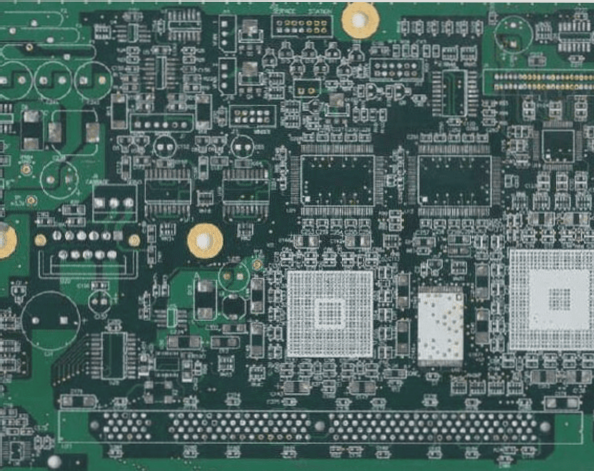

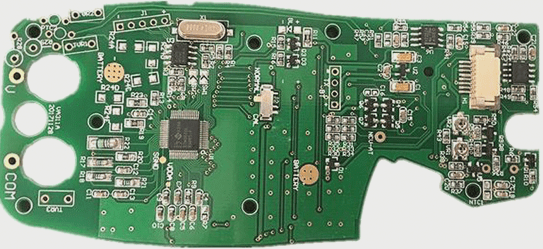

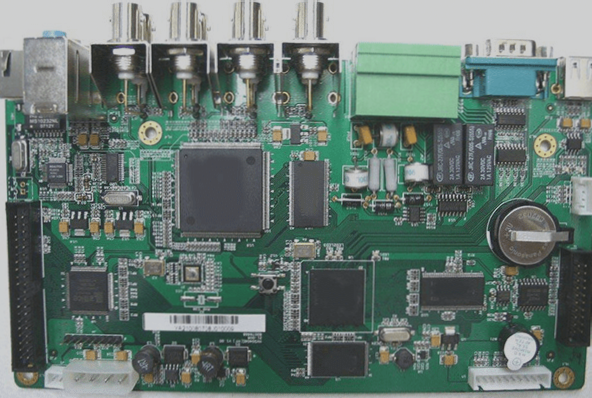

PCB circuit board connectors are versatile electronic components used to connect various devices and appliances, and choosing the right one involves focusing on quality from reputable manufacturers rather than just price.

PCB Circuit Board Connectors and Procurement Strategies Read More »