A Case Study on Shared Clients of Wellcircuits and Ponoko – News – Wellcircuits

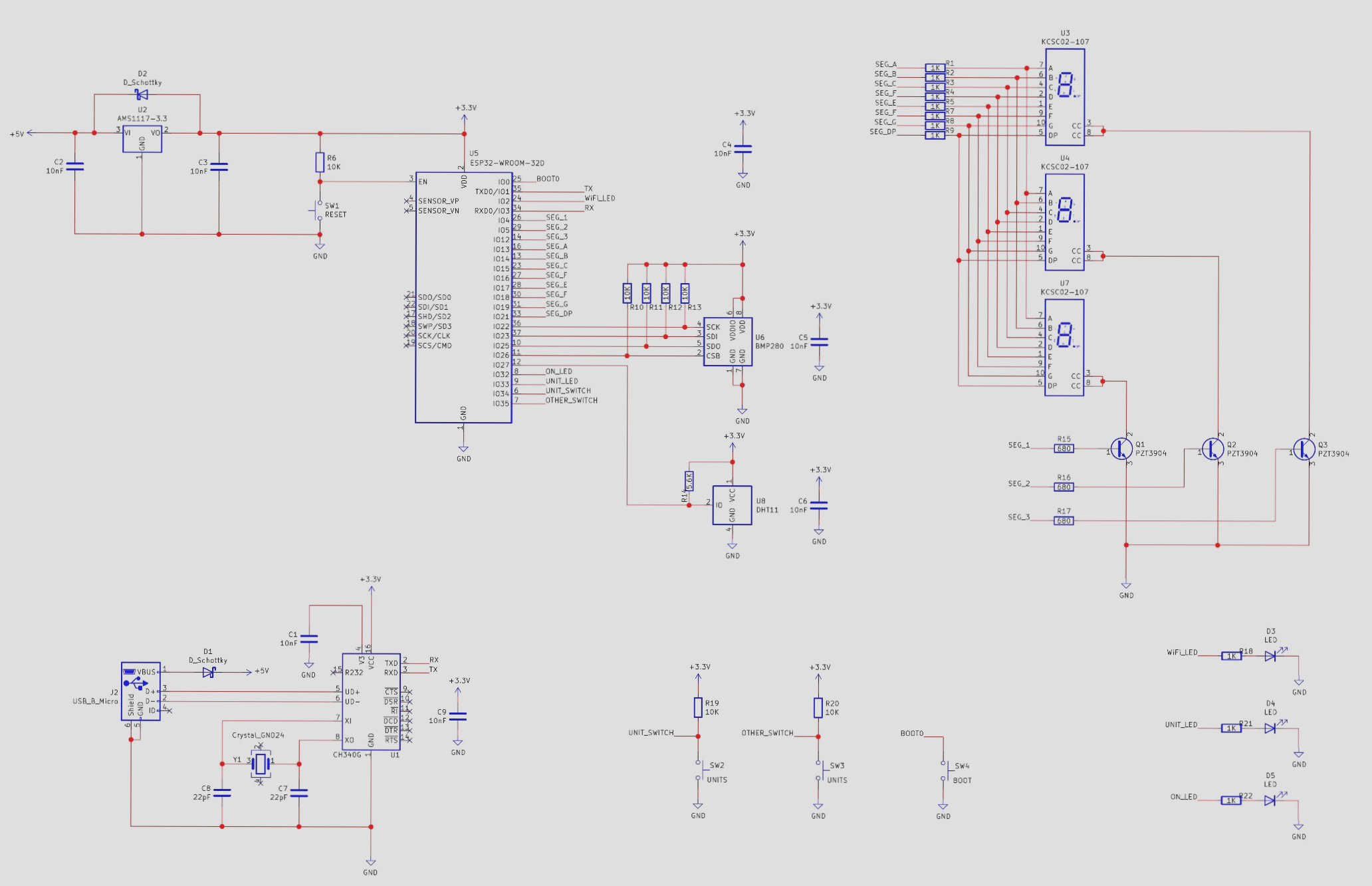

Part 1 – Designing our PCB and first prototype enclosure Taking a design from concept to production is no small feat but careful planning and proper use of prototyping construction methods can greatl

A Case Study on Shared Clients of Wellcircuits and Ponoko – News – Wellcircuits Read More »