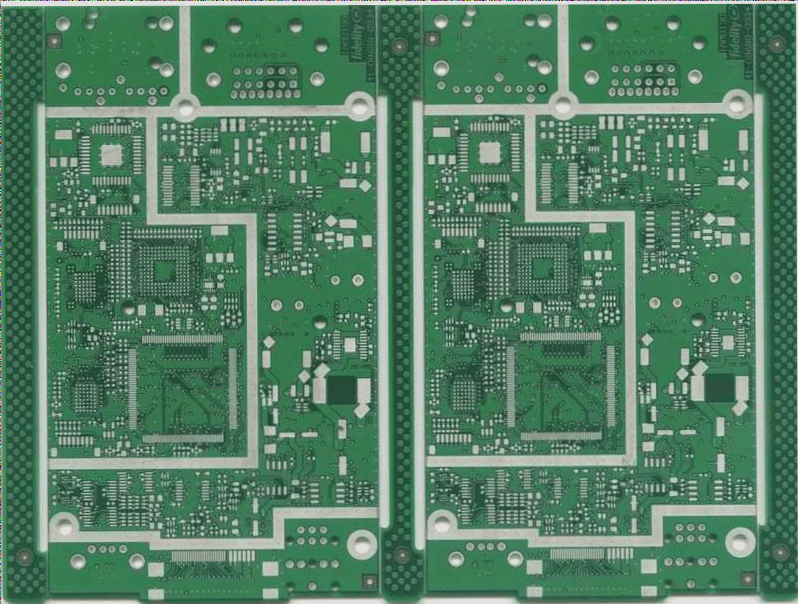

How to Determine the Temperature Tolerance of a PCB

The solder paste printing test requires using a soldered PCB for accurate thermocouple testing, selecting representative test points based on temperature zones, securely attaching thermocouples, and analyzing the temperature curve data to ensure proper reflow soldering without exceeding temperature limits.

How to Determine the Temperature Tolerance of a PCB Read More »