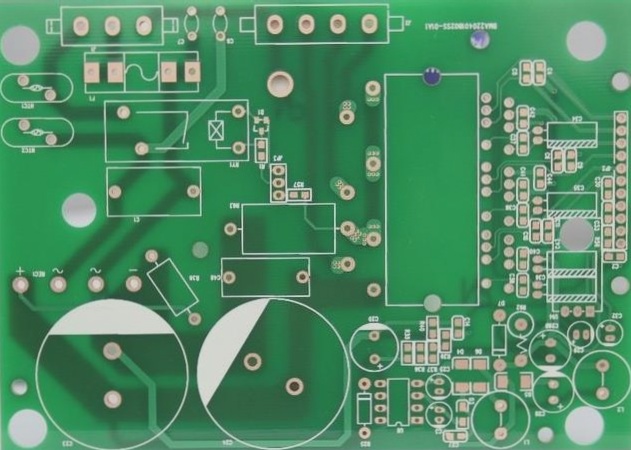

PCBA Soldering Principles and Manual Soldering Techniques for PCBA Boards

Soldering, both automated and manual, is essential for creating reliable electrical connections in printed circuit board assemblies (PCBA), ensuring component attachment, and maintaining circuit functionality, with manual soldering particularly crucial for repairs and troubleshooting.

PCBA Soldering Principles and Manual Soldering Techniques for PCBA Boards Read More »