Issues and solutions related to Copper Clad Laminate in PCB manufacturing: Part 1

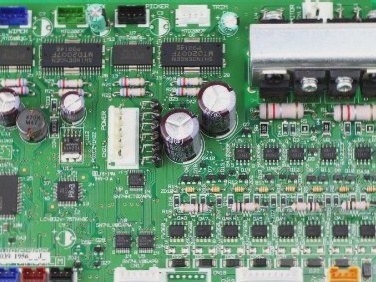

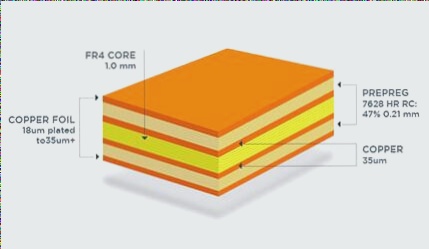

Understanding the role of PCB copper clad laminate material is essential for solving manufacturing problems, such as quality issues linked to substrate material. Common PCB laminate issues can be identified and prevented by including them in the specification and verifying batch numbers. Surface problems, like poor adhesion and unetched areas, can be addressed by using proper handling practices and following recommended cleaning procedures.

Issues and solutions related to Copper Clad Laminate in PCB manufacturing: Part 1 Read More »