Effective Strategies to Minimize the Expenses of Printed Circuit Board Fabrication 1

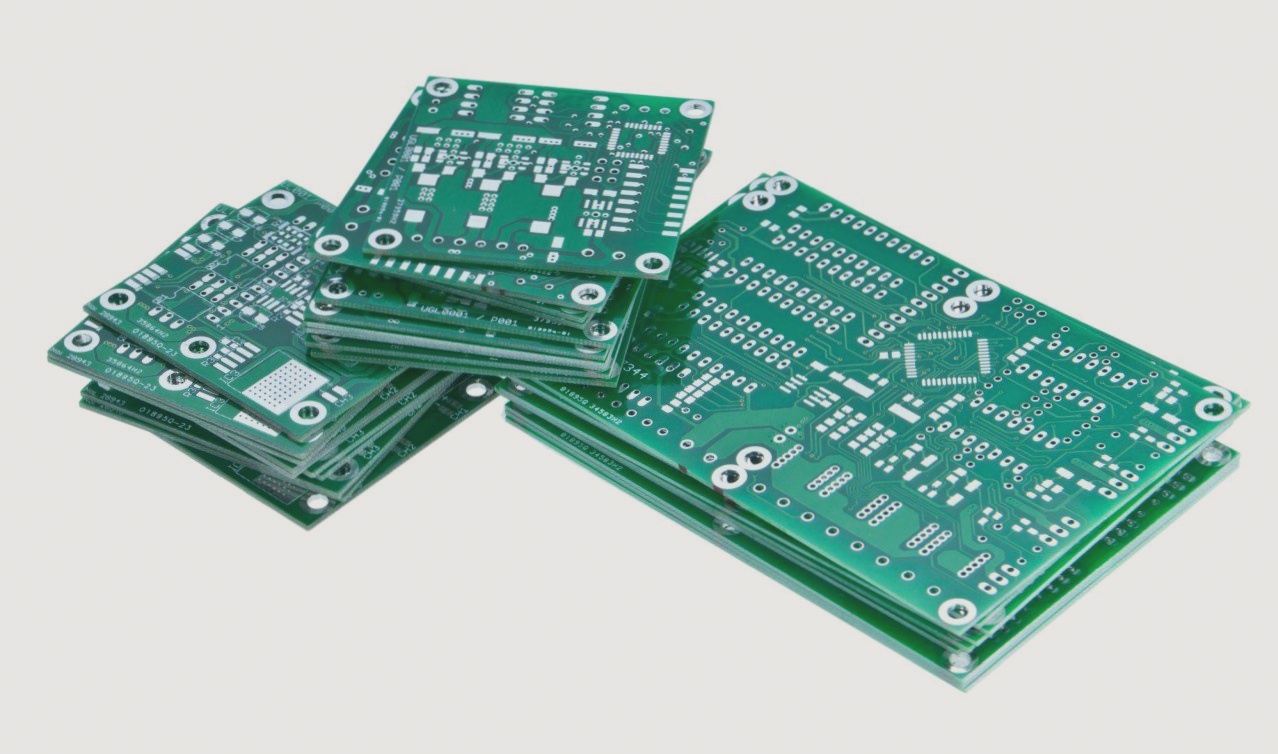

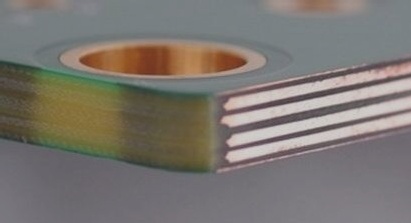

Optimizing PCB size, layer count, and using cost-effective CEM-3 material are effective measures to reduce manufacturing costs.

Effective Strategies to Minimize the Expenses of Printed Circuit Board Fabrication 1 Read More »