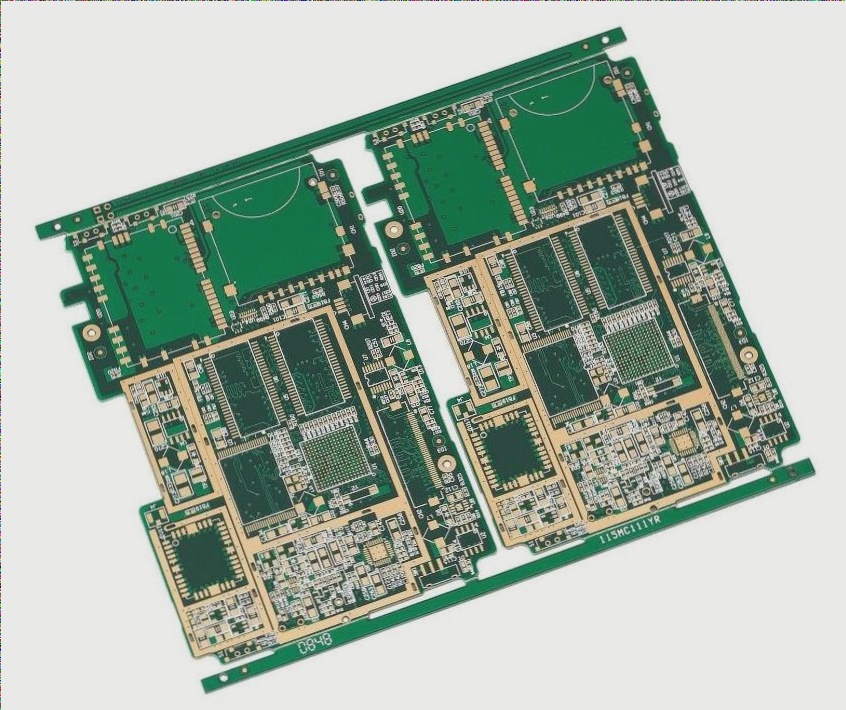

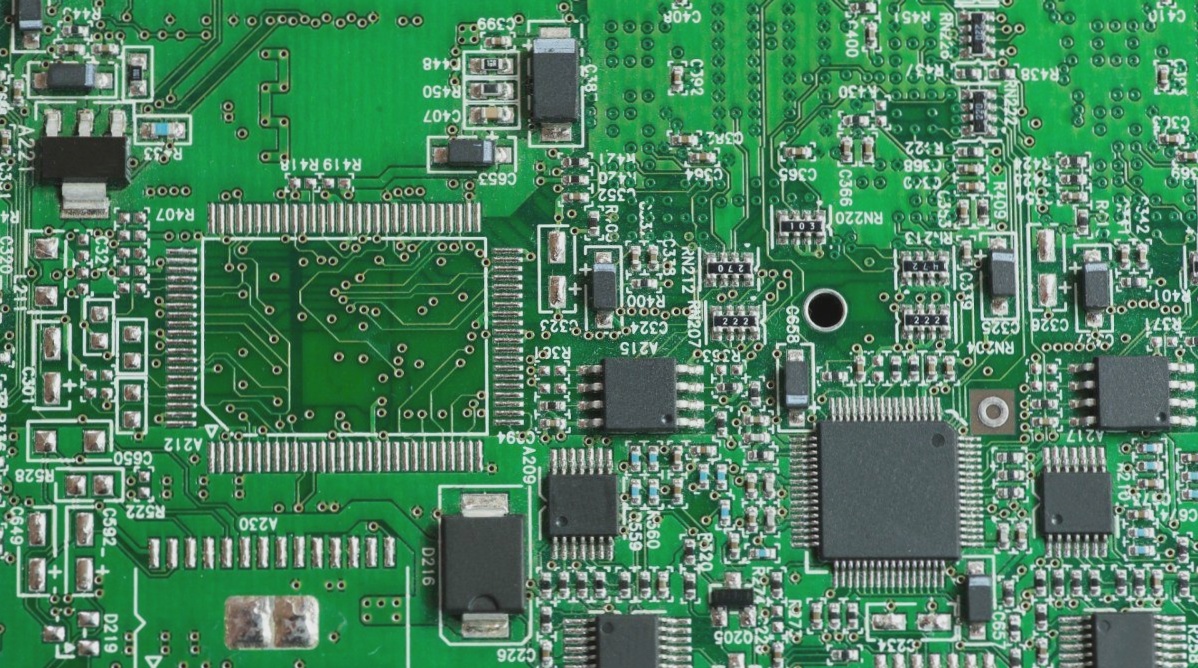

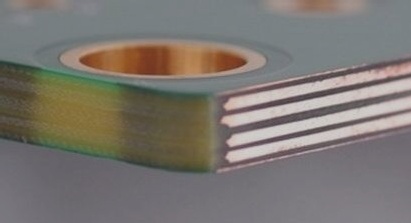

As a PCB expert, I specialize in filling various types of resin plug holes, such as mechanical through holes and blind buried holes, using conductive and non-conductive resin. Filling these holes is crucial for reducing vacuum during lamination, preventing surface depression, achieving inter-layer interconnection, and enabling higher-density wiring. In HDI PCB processing, resin plug holes are essential for BGA parts and meeting the design requirements of thin dielectric layers. Resin plug holes also improve the mechanical strength and durability of PCBs while isolating different circuit layers to enhance performance and stability. The application of resin plug-hole technology in PCBs is increasingly widespread, especially in multi-layer circuit boards with high precision, as it effectively solves various manufacturing and performance issues that cannot be addressed by other methods.