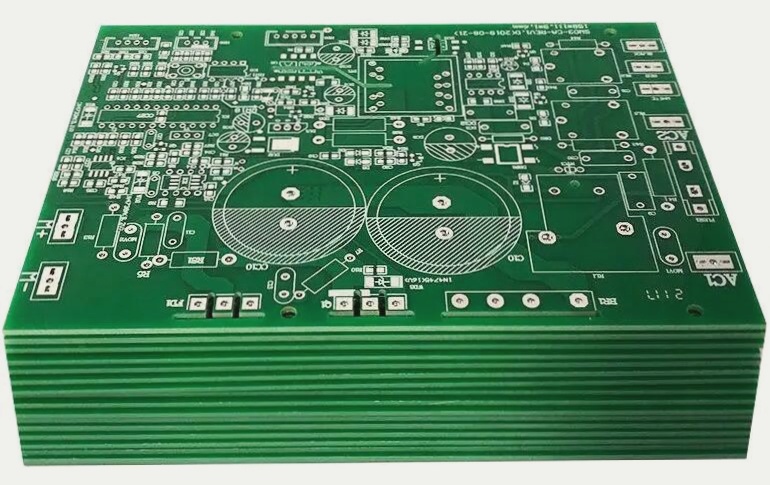

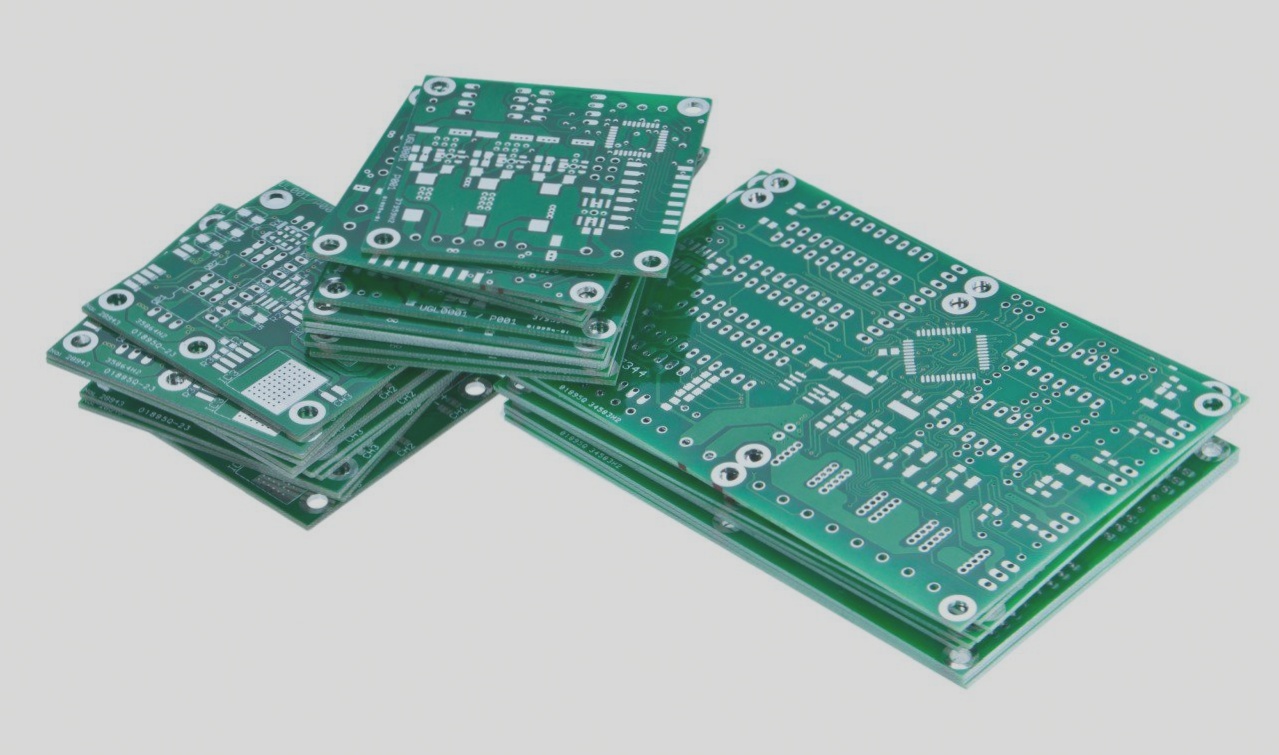

The key points can be summarized as follows: Multi-layer blind, buried, and blind-hole structure printed circuit boards (PCBs) are fabricated using the “sub-board” production method, which necessitates precise positioning due to multiple pressing, drilling, and hole plating processes. Buried, blind, and through-hole (multi-layer blind-buried circuit boards) combined technology is an important method for increasing the density of printed circuits. Buried and blind via holes are generally small in size and interconnected with the nearest inner layer, reducing the number of holes and simplifying the manufacturing process, thereby increasing the density of interconnections. The adoption of the pin front positioning system of ordinary multi-layer circuit board production unifies the graphic production of each layer, creating conditions for successful manufacturing of ultra-thick single chip PCBs.