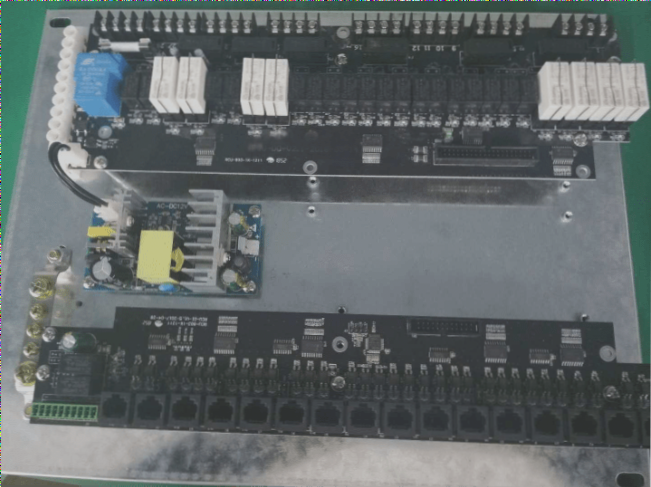

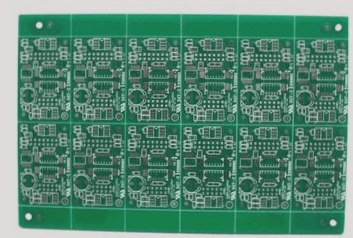

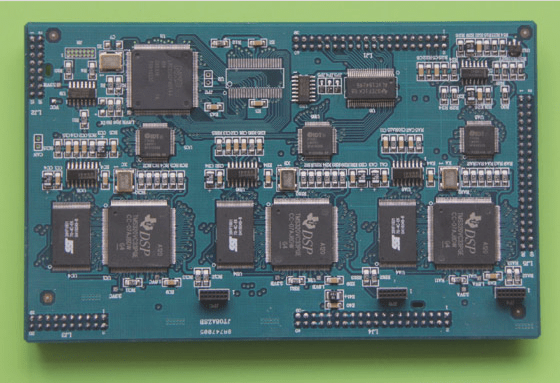

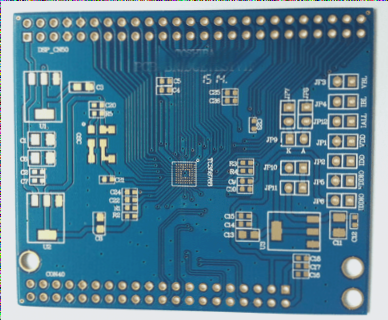

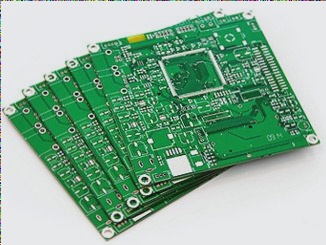

Basic Classification of Core PCBs

The article categorizes printed circuit boards (PCBs) based on layer count—single-sided, double-sided, and multilayer—and material type—flexible, rigid, and rigid-flex—highlighting their essential roles in electronic components and their specific applications.