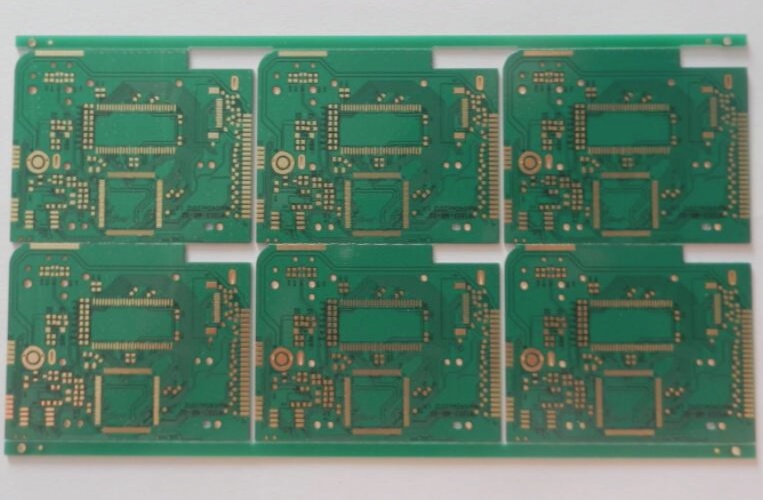

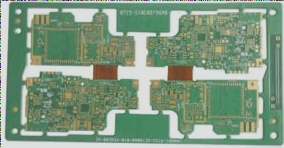

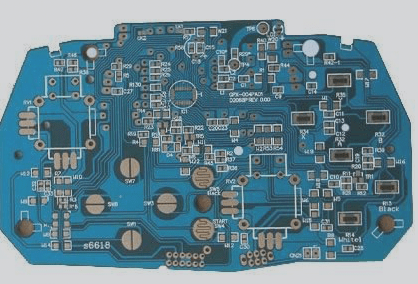

PCB manufacturing cost and board flexibility (bending tolerance)

The choice between even and odd-layer PCBs depends on factors like cost, manufacturing complexity, and risk of bending, with odd-layer designs potentially reducing material costs but increasing processing difficulty and risk of warping.

PCB manufacturing cost and board flexibility (bending tolerance) Read More »