What processes does PCB board corrosion undergo?

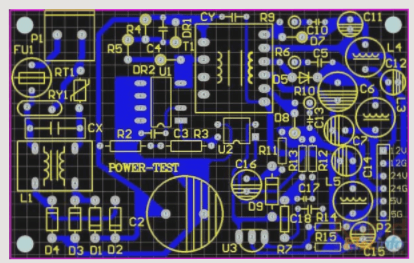

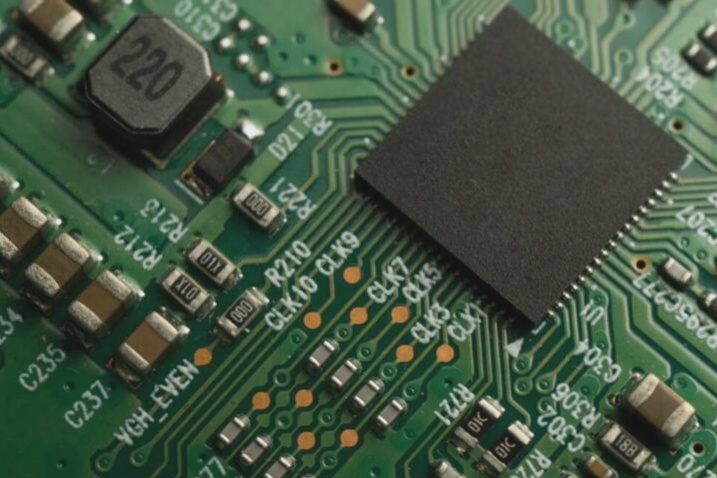

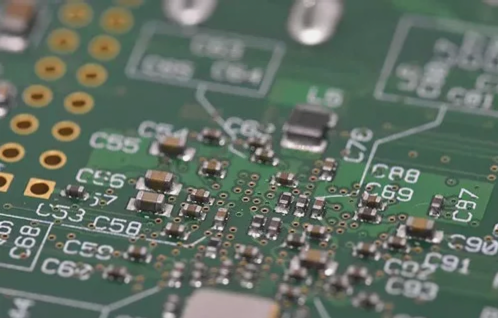

PCB boards are essential electronic components used across various industries, providing electrical connectivity and supporting components, with 4-layer and 6-layer boards being the most common.

What processes does PCB board corrosion undergo? Read More »