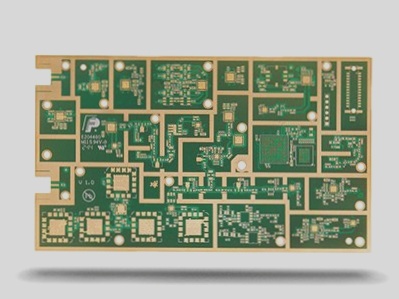

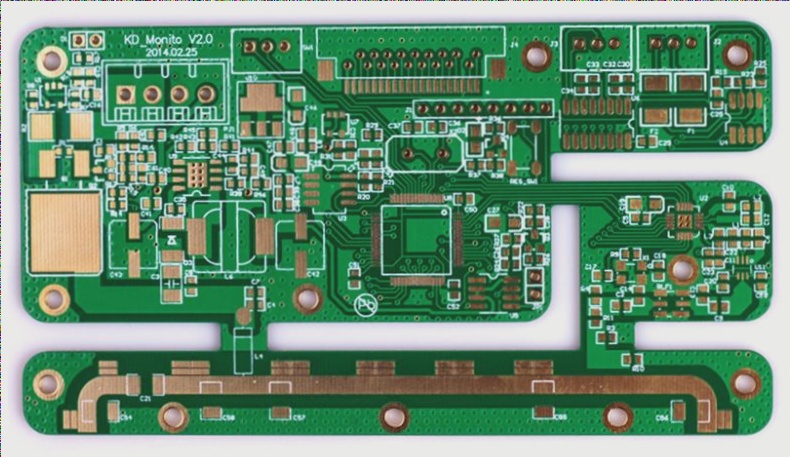

PCB board design specifications for switching regulator production.

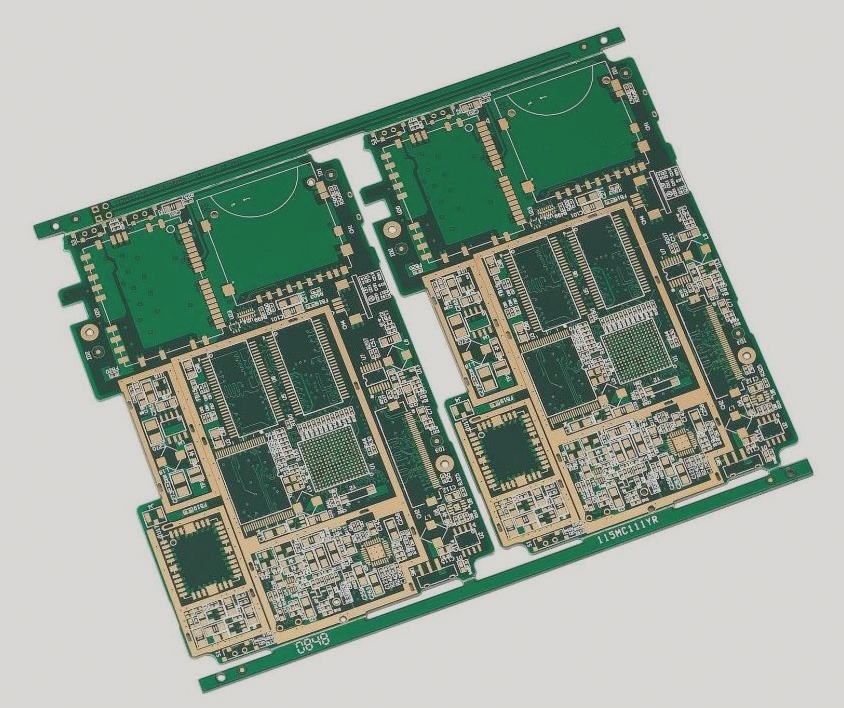

The PCB board is crucial in power supply design, with key considerations including electrical safety, component layout, high-frequency processing, global routing, and inspection for reliability.

PCB board design specifications for switching regulator production. Read More »