How to Maintain PCBs to Prolong Service Life

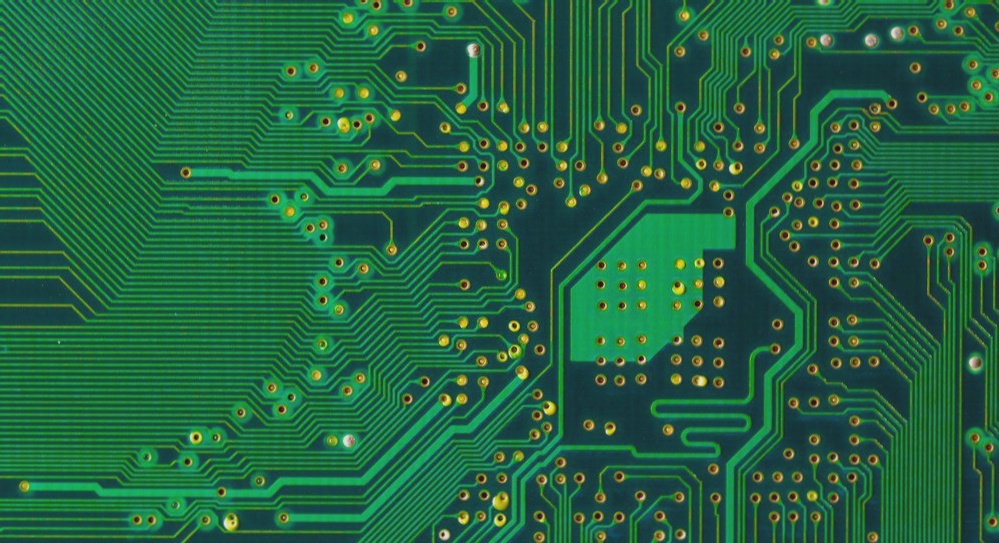

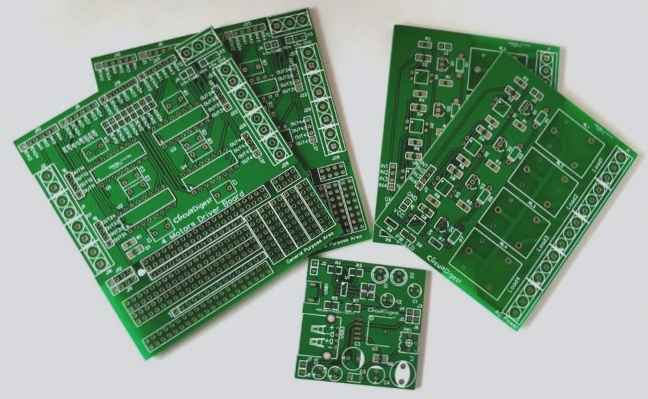

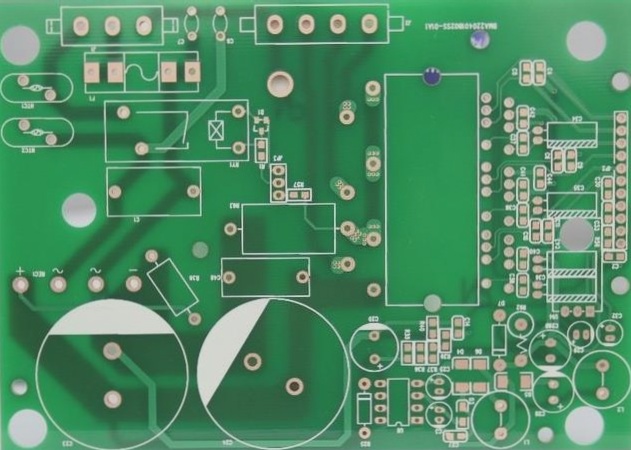

PCB boards have evolved to improve precision, density, and reliability, and require regular maintenance to ensure optimal performance. WellCircuits Limited offers a variety of high-precision PCB circuit boards to meet customer needs.