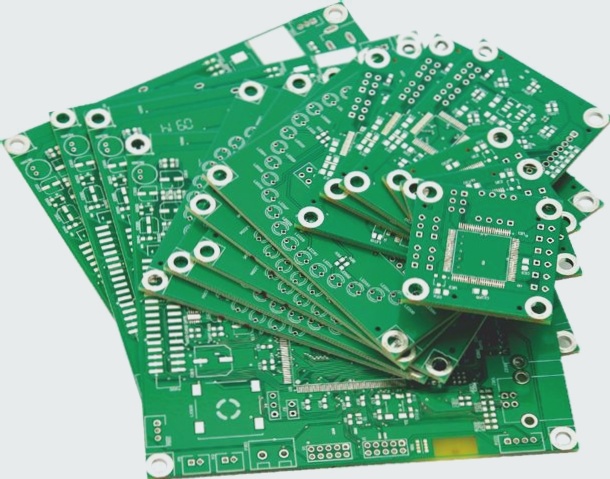

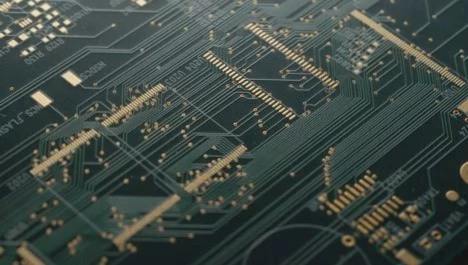

Methods for Processing PCB Circuit Boards in Wuxi SMD Fabrication

PCB circuit boards are small but essential in electronics, requiring precise soldering techniques and careful processing to ensure quality and efficiency in assembly.

Methods for Processing PCB Circuit Boards in Wuxi SMD Fabrication Read More »