Why are PCBs Green? – Flexible PCB – Wellcircuits

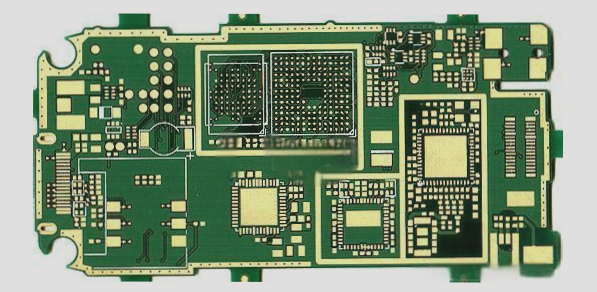

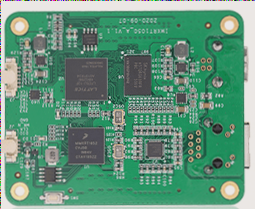

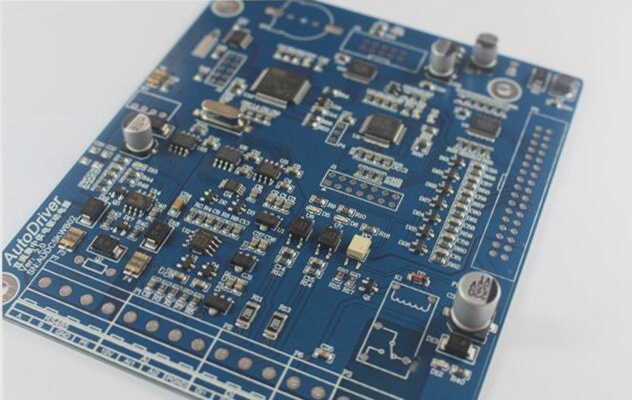

回路基板の構造回路基板は主にパッドオーバーホール取り付け穴ワイヤ部品コネクタパディング電気境界などで構成されている各コンポーネントの主な機能は以下の通りですパッド部品のピンを溶接するための金属穴貫通金属貫通と非金属貫通があり金属貫通は層間素子ピンを接続するために使用される取り付け穴回路基板を固定するワイヤ部品ピンの電気ネットワークを接続するための銅フィルムコ

Why are PCBs Green? – Flexible PCB – Wellcircuits Read More »