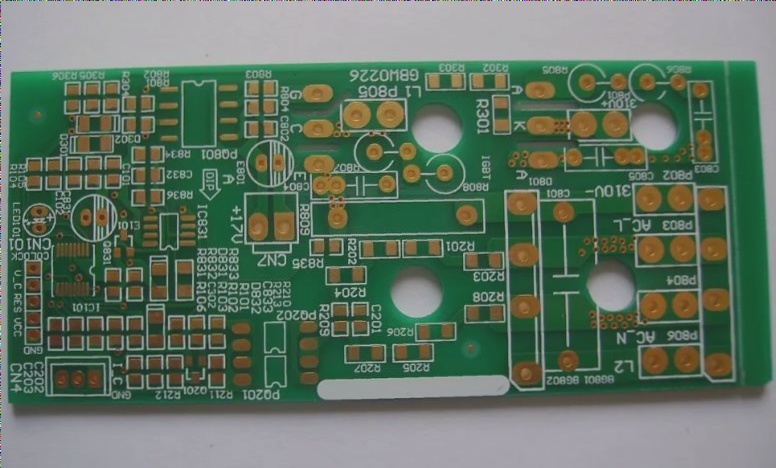

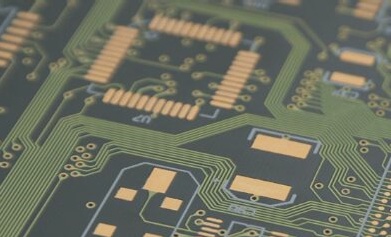

Why is there no copper in the PCB hole’s copper plating?

The text discusses the importance of substrate selection, pre-treatment, and surface cleaning in PCB manufacturing, highlighting how variations in resin systems, material properties, and process steps such as drilling and copper plating can impact quality and reliability, emphasizing the need for careful coordination and specialized treatment methods to avoid defects and ensure proper adhesion.

Why is there no copper in the PCB hole’s copper plating? Read More »