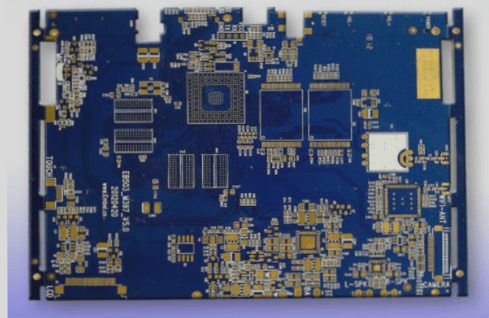

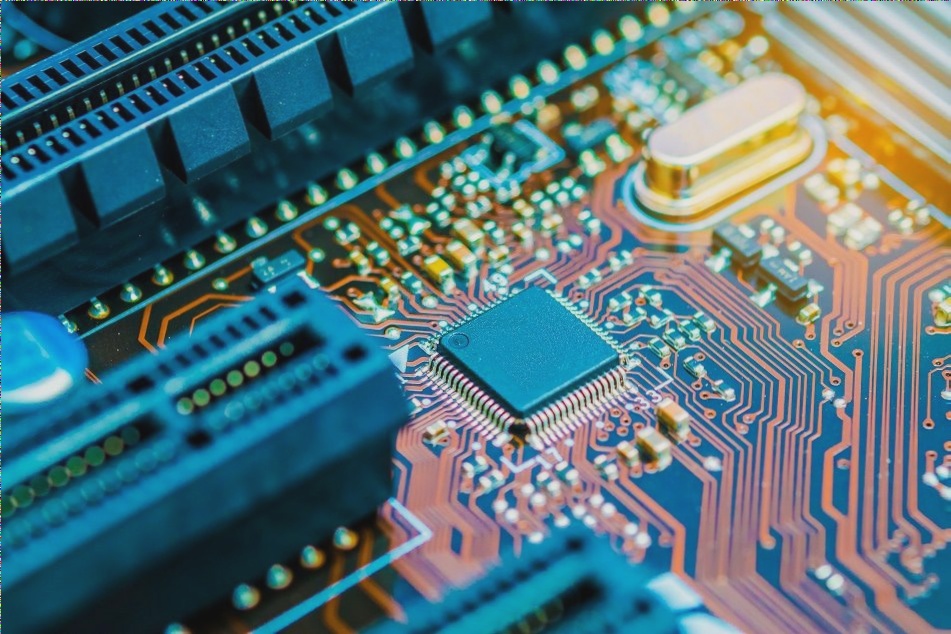

Why PCB Boards Deform and How to Prevent It

Understanding PCB Board Deformation and Prevention** PCB boards often deform during processing, especially in reflow soldering, leading to issues like misalignment and component damage. To prevent this, maintaining strict deformation limits and ensuring even distribution of materials and structures in the PCB are crucial for high-precision assembly.