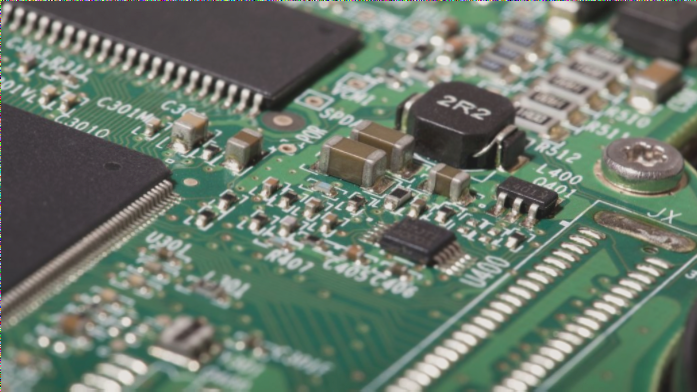

Are you familiar with the PCB design process?

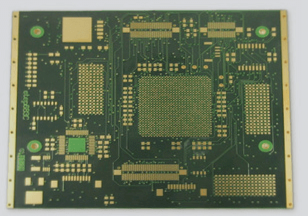

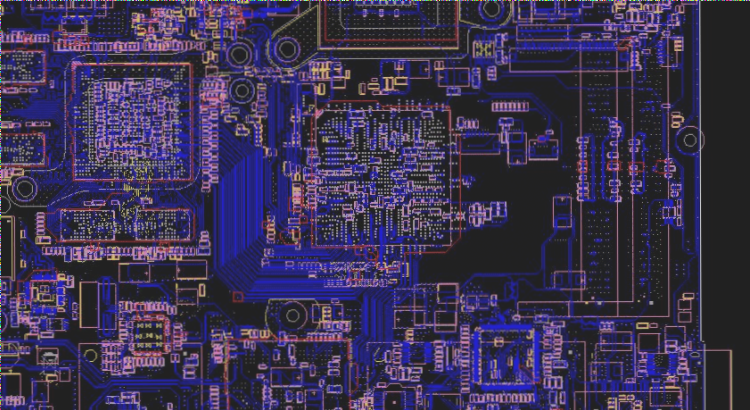

The article outlines the six main steps of the PCB design process, including netlist input, rule setup, component placement, routing, inspection, and review, with a focus on methods, precautions, and best practices for layout, routing, and design verification, while maintaining technical accuracy and clarity.