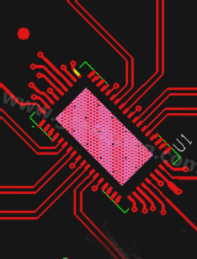

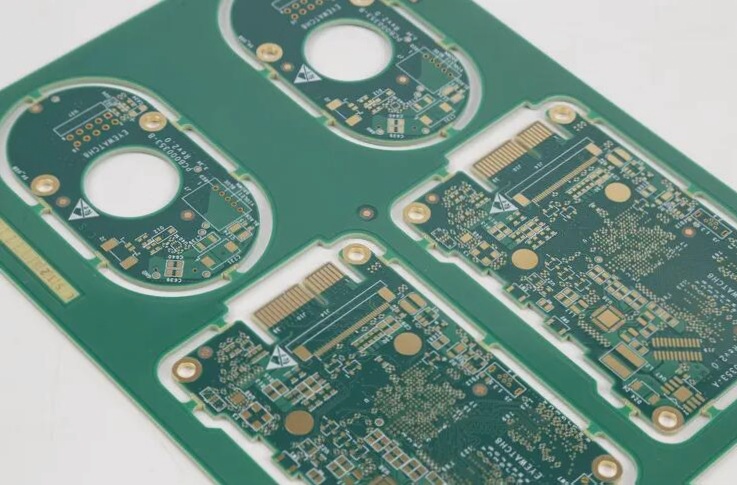

Experience in PCB Circuit Board Design and Layout

A concise summary of the text is: **PCB design requires balancing correctness, reliability, reasonableness, and economy, with careful attention to grounding, component placement, routing quality, and post-production issues to ensure functionality, efficiency, and long-term reliability.**

Experience in PCB Circuit Board Design and Layout Read More »