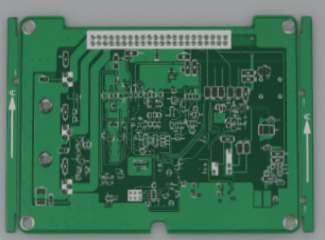

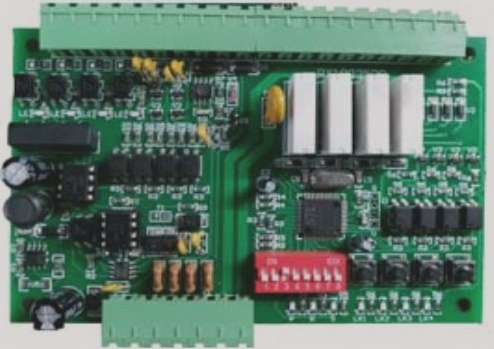

What is PCB design and prototyping?

Prototyping in PCB design is essential for testing and refining concepts before full production, helping engineers validate functionality, minimize risks, and avoid costly rework, with various types of prototypes and specialized software tools supporting different stages of development.