Understand the three types of drilling processes in PCB fabrication.

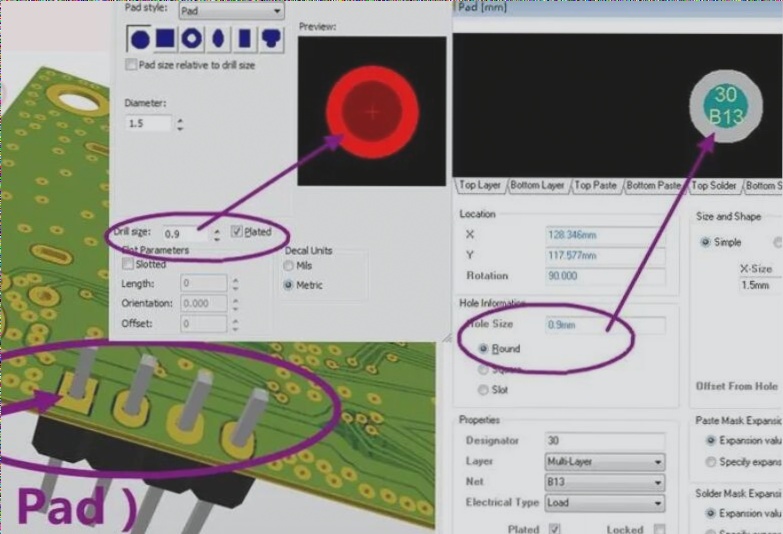

PCB drilling includes through holes, blind holes, and buried holes, with vias serving as electrical connections between layers, where blind and buried vias optimize space and conductivity, but are more complex and costly to manufacture.

Understand the three types of drilling processes in PCB fabrication. Read More »