What is the function of AOI (Automated Optical Inspection) testing technology?

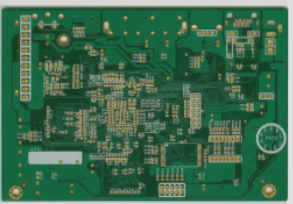

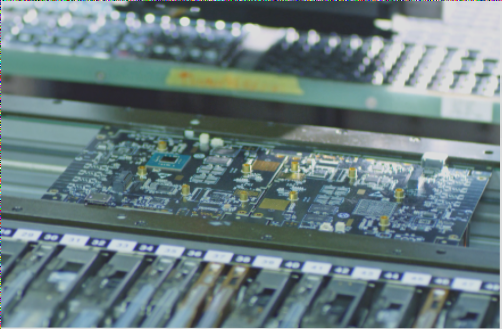

AOI (Automated Optical Inspection) is an advanced electronic testing technology used in PCB duplication, which helps detect defects during the production process by scanning PCBs and comparing them to predefined parameters, ensuring both end-product quality and process tracking across various stages such as solder paste printing, component placement, and reflow soldering.

What is the function of AOI (Automated Optical Inspection) testing technology? Read More »