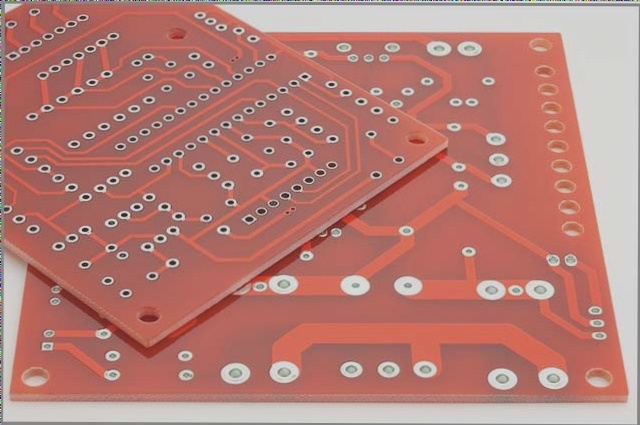

Introduction to UV Laser Processing in PCB Industry

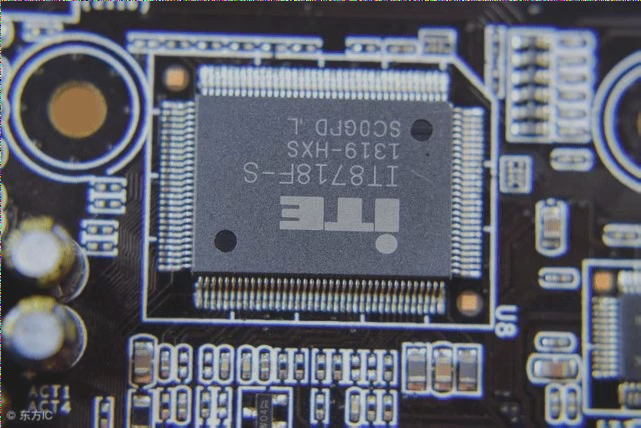

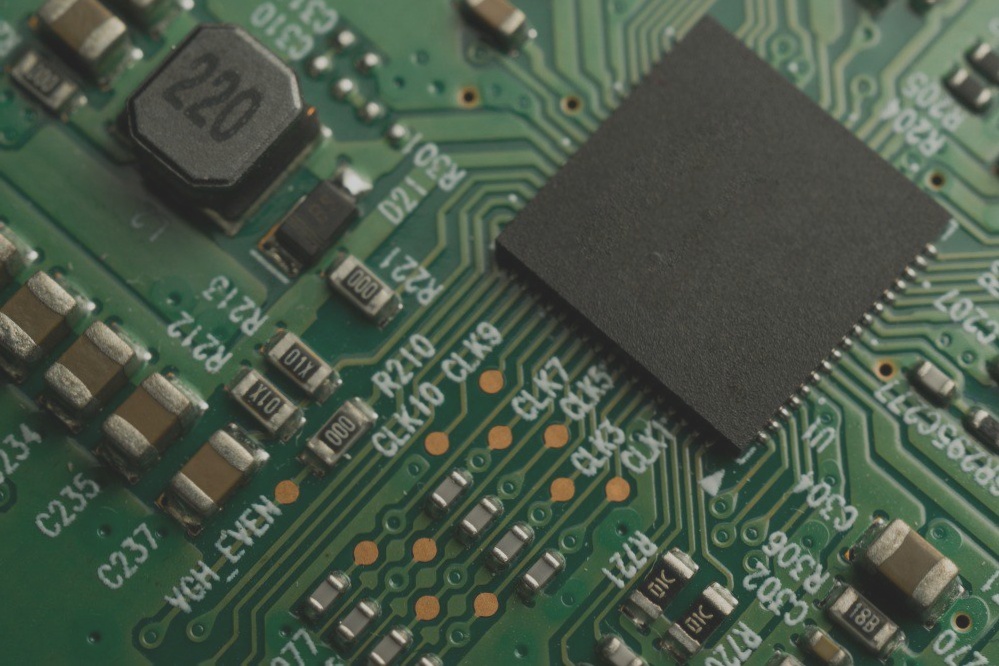

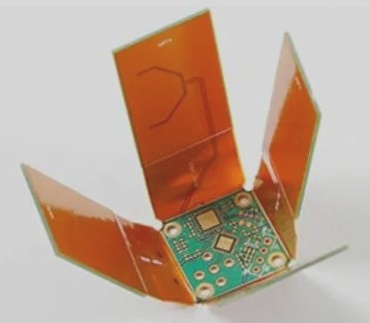

UV laser technology, pivotal in PCB fabrication, offers precise cutting with minimal thermal impact, revolutionizing manufacturing across industries, outperforming CO2 alternatives in efficiency and safety, and enabling seamless integration into production workflows.

Introduction to UV Laser Processing in PCB Industry Read More »