What is the process for selecting the suitable thickness for a PCB board?

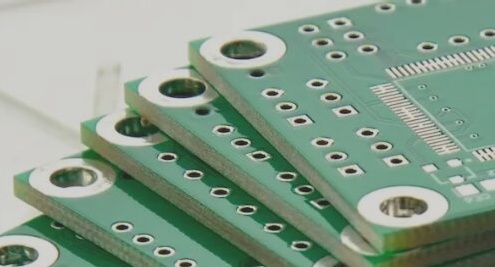

PCB board thickness is an important consideration for ensuring the performance and reliability of the PCB, and it is determined by factors such as application requirements, copper thickness, substrate material, number of PCB layers, signal type, type of through-hole, and operating conditions.

What is the process for selecting the suitable thickness for a PCB board? Read More »