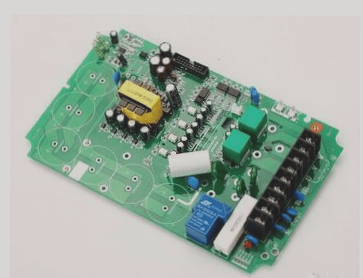

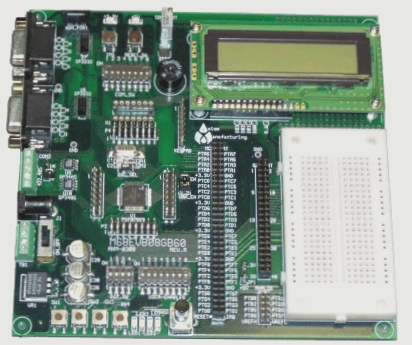

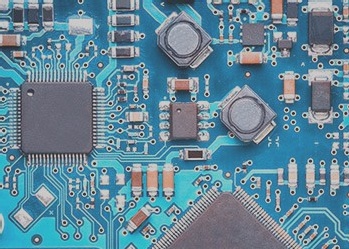

Key Reasons for the Significance of AGVs in the PCB Industry

AGV technology is essential in the PCB industry for reducing labor dependence, improving production efficiency, ensuring high precision, and enhancing overall automation, which helps tackle labor shortages, reduce costs, and boost competitiveness.

Key Reasons for the Significance of AGVs in the PCB Industry Read More »