Why Green is the Most Common PCB Color – A Technological Perspective – Wellcircuits

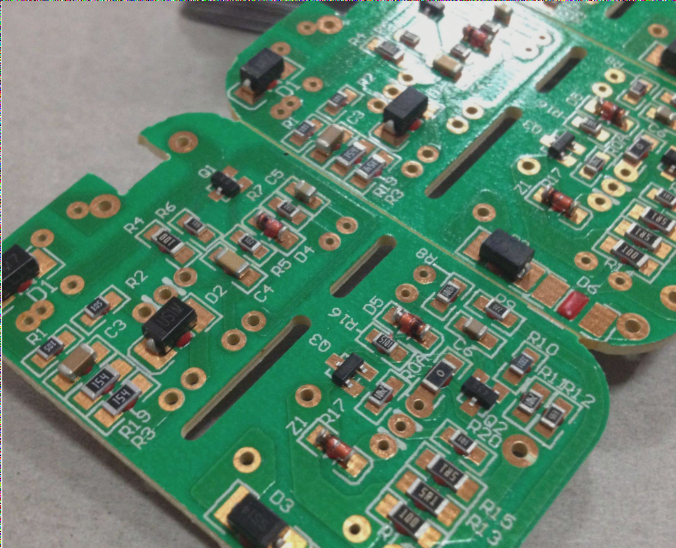

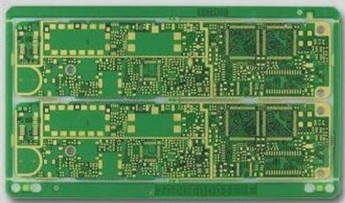

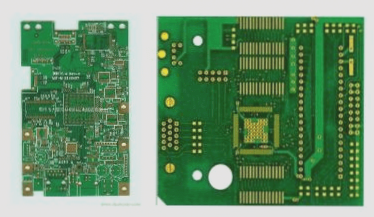

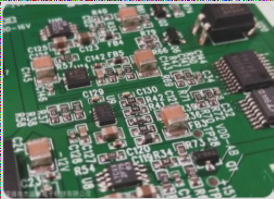

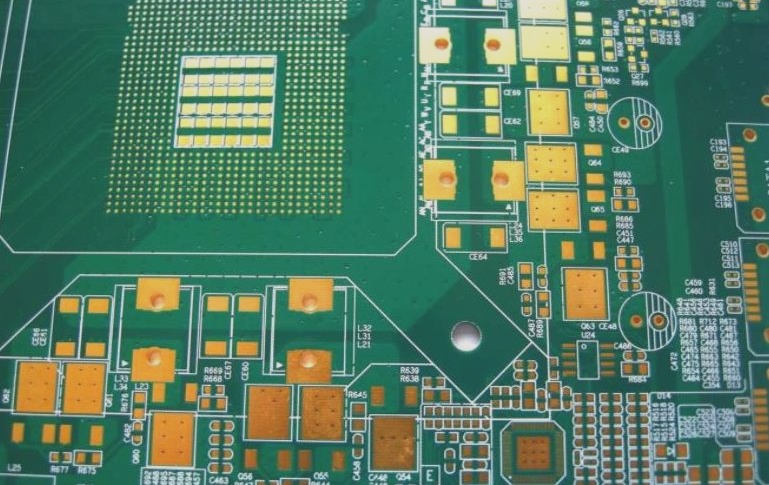

PCB board surface color is actually the color of solder First the solder inhibitor can prevent the occurrence of component miswelding Second it can delay the service life of the device and preven

Why Green is the Most Common PCB Color – A Technological Perspective – Wellcircuits Read More »