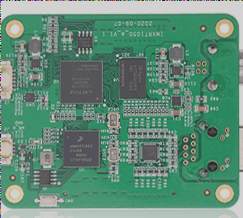

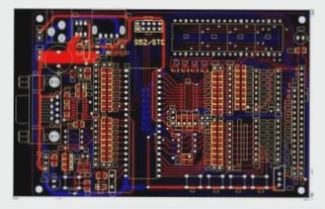

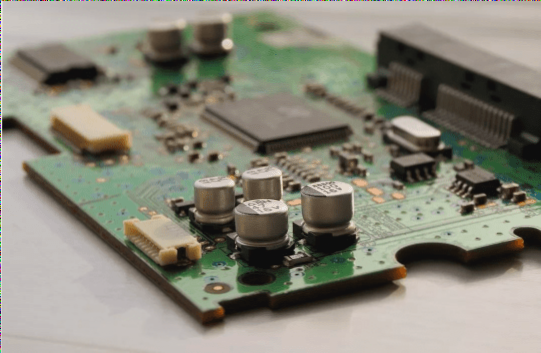

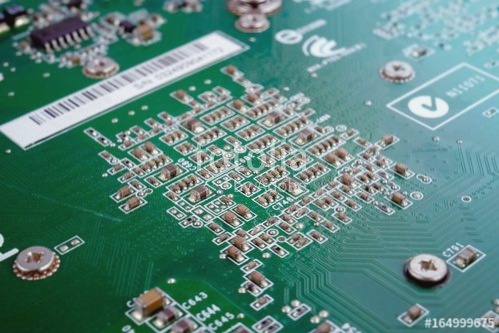

How crucial is the PCB layout design?

PCB design requires careful planning and early identification of constraints to ensure efficient, manufacturable, and cost-effective layouts that meet both functional and regulatory requirements, with the use of DFM tools playing a key role in optimizing the design for production.