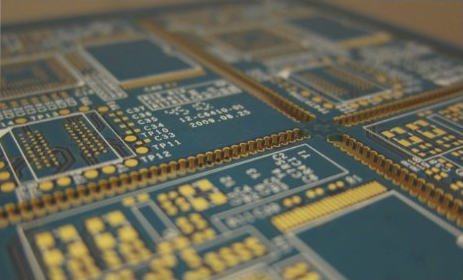

PCB reverse engineering, circuit board layout, and schematic design

A PCB copy board involves reverse engineering a physical circuit board to recreate its design, including the schematic, layout, and components, enabling the exact replication of the original board.

PCB reverse engineering, circuit board layout, and schematic design Read More »