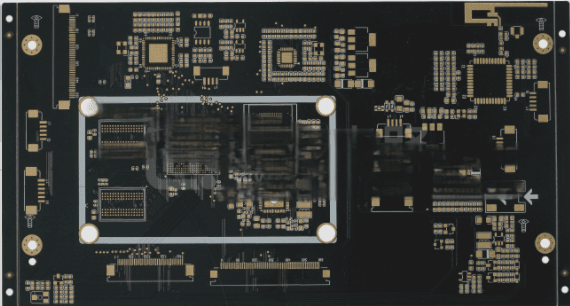

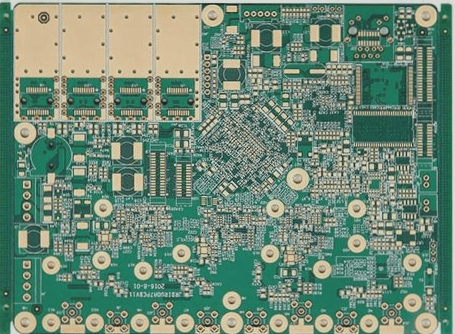

Strategies for Reducing Costs in PCB Assembly via SMT Surface-Mount Technology

The article discusses strategies to reduce costs in PCB assembly while maintaining quality, emphasizing design simplifications, efficient PCB layouts, optimized bill of materials, and the careful selection of reliable manufacturers with advanced technology and certifications.

Strategies for Reducing Costs in PCB Assembly via SMT Surface-Mount Technology Read More »